Photo 1

Photo 1

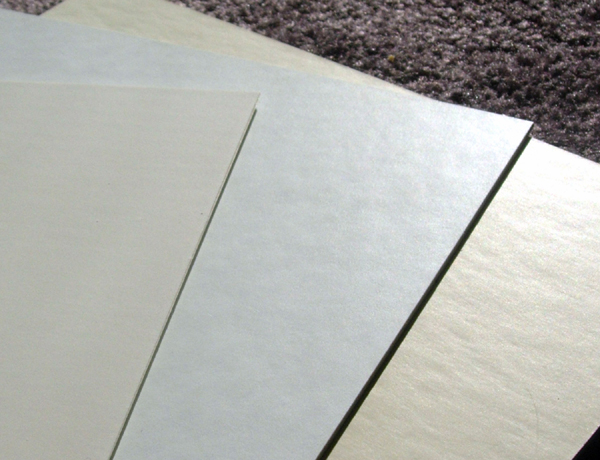

The HA board left has a very distinct adhesive pattern while the applied adhesive right is much smoother.

When a heat activated adhesive comes preapplied to a mount board it is known as an HA board, and use of such boards have become commonplace in today's frame shop. HA foam boards were developed as a time saving alternative for production framers and the OEM market, originally developed to equal the cost of rolled dry mount tissue and a mount board. Over time it has become a very is cost effective alternative cutting tissue+board costs by nearly one third.

HA Foam Center Boards

HA foam boards are an extruded polystyrene core substrate with clay coated or neutral pH facing papers that have adhesive applied to one side. There are three categories of preadhesived HA foam boards, all based on the adhesive: permanent boards have a 185ºF base bonding temperature with a suggested dwell time of 2-3 minutes in mechanical press; most removable boards have a lower activation temperature of 150ºF-160ºF with a shorter dwell time of 1-3 minutes in mechanical press; and reversible boards have a low temperature and short dwell time combination of 150ºF at 15 seconds - 1 minute in a mechanical press. These boards are available as ⅛" to 3/16" thicknesses in both white and black in assorted standard industry sizes from numerous manufacturers. Use in hot vacuum presses will require the draw time of the unit to be added to manufacturer suggested dwell times for the HA product.

As mentioned above HA boards are available as permanent, removable and reversible. Permanent HA boards bond in the press as all layers reach required bonding temperature, and the bond may only be broken with a chemical solvent. Removable HA boards adhesives activate as all layers reach temperature in the press, but bond as they cool under a weight. This adhesive reactivates when placed back under heat and the layers may be peeled apart prior to cooling. Reversible HA boards have revolutionized the concept of preservation mounting beyond starch hinging. These boards activate under heat, bond when cooled, and may be reactivated when placed back under heat.

Reversible HA Boards

Removable means the adhesive bond is broken and the art may be removed, but the removed art will forever have some degree of adhesive residue. Reversible means the art may be removed from the substrate and returned to its original state with no adhesive absorption or residue. This makes it a true preservation dry mount process.

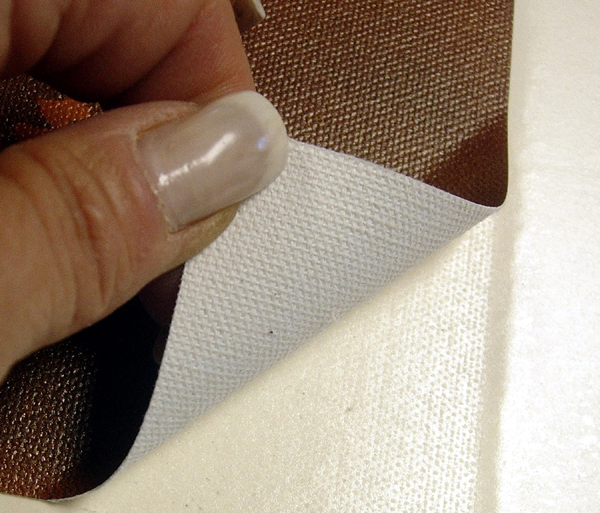

The two reversible HA boards available today—Bainbridge Artcare Restore and Kool Tack Preserve—allow art to return to its original state once separated from the board. Mounting is low temperature 150ºF to 160ºF for a short dwell time of 15 -30 seconds in a mechanical press. Removal may be achieved by reheating the board to 160ºF for 1 minute—in a mechanical press—which reactivates the adhesive. Remove the art by breaking the bond along an entire width of the short edge of the art with a thin metal or plastic spatula the width of the art and gently shearing it from the backing with a beveled mat board scrap. Once separated from the backing, turn the art face down on a clean rigid surface and gently rub any remaining adhesive from the back of the art with a gloved hand. Any remaining residue may be brushed off as a powder leaving no saturation.

Basic TTPM

Though it is the applied adhesive that determines the permanence, removable, or reversibility of any given HA board, it is operator control over TTPM—time, temperature, pressure, moisture—that controls and achieves a successful bond. Though manufacturers all suggest times and temperatures for designated HA materials, it is up to each individual framer to determine any adjustments depending upon their own equipment. It is best to add either time or temperature but generally not both.

Elevation—altitude of the location city—has been known to impact required temperatures, sometimes requiring an increase from 150ºF to 160ºF for correct bonding. Variations in project dimensions or layers (time), board thickness (pressure), humidity control (moisture), and equipment draw (time) are all examples of other elements that might suggest an adjustment in bonding time or temperature. To verify proper bonding check for tear or T-peel strength after adhesives have set after cooling. Only in the event of bond failure should the dwell time or temperatures be adjusted.

Adhesives

Dry mount roll adhesives are easiest to understand when examined by their four basic characteristics. Once the type of bond (permanent or removable); physical composition (tissue-core or film); porosity (breathable or nonbreathable); and acidity level (tissue pH) have been identified, then all adhesives may be compared as apples to apples. Preadhesived boards are like a roll of adhesive where the carrier is no longer between two thin layers of adhesive, but rather the carrier is the foam board itself.

HA foam center boards have a smoother surface than HA paper core boards. HA boards that have a surface texture or pattern resulting from the application process of a liquid adhesive (photo 1) might encourage a surface texture under thin paper prints. Though it melts and semi-levels during the bonding process it may still create a subtle orange peel (photo 2). Keep in mind it may not be the substrate, adhesive application, but a commercial release board that transfers an orange peel to a foam board mounting. Foam boards are soft and pliable and easily pick up indentations from dirt, wrinkled release paper, or a release board with a prominent orange peel (photo 3). Creating your own single or double sided release boards in-house allows for best control over the surface smoothness (see PFM, March 2008, "In-House Release Boards").

Photo 1

Photo 1

The HA board left has a very distinct adhesive pattern while the applied adhesive right is much smoother.

Photo 2

Photo 2

Orange peel may be the result of texturally applied adhesive, lumpy HA board or commercial release boards. The orange peel shows under a paper print (L) mounted to HA board. Often HA foam center boards are smoother than paper core versions.

Some HA boards have a heavier application of adhesive allowing them to be used with fabrics or nonabsorbent photos, while others are better geared to thinner porous papers. Orange peel is somewhat expected under nonabsorbent RC photographs, resulting from their resin coating that conforms to all the highs and lows of the substrate surface (photo 4).

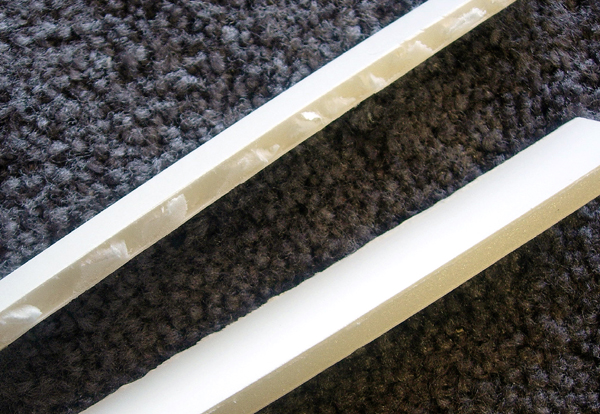

Photo 3

Photo 3

In-house release boards (L) allow for control over the smoothness of the surface. Center is an unused commercial board, while right is a retired commercial board. The orange peel texture does not smooth out over time and use. Compare the texture of board on the right to the visible orange peel texture of the left photo in #4.

Photo 4

Photo 4

Orange peel is somewhat expected under nonporous, nonabsorbent RC photographs, as is seen in the photo, trapped air (L) and varying degrees of surface texture occurs on different boards.

The HA Test

In June 2006 I conducted a test of major manufacturer HA boards, available at that time, in the framing and photo markets. Products included those from Alcan, Bainbridge, Bienfang, Gilman, Hartman and Savage. In 2007, a new product from Kool Tack emerged, said to rival Restore, and though only briefly tested for mention in this article has not been fully investigated.

Boards were checked for surface smoothness of adhesive application, finger denting, foam memory, tactile feel, and mounted at suggested times and temperatures. Single Step, Gilman, and HartMount all remove from their case with a bow in them, while Restore and SpeedMount warped when vacuum mounted, but flattened when cooled under weight. Some brands cut cleanly every time when being sized, while others bunch and grab more times than not (photo 5). All surfaces were closely examined for pin holes, indentations, die cut crush, and workability.

Photo 5

Photo 5

Always use a sharp new blade when cutting foam boards, but even then some foam boards cut cleanly every time, while others will routinely bunch and grab.

Bonding Results

Eleven manufacturer boards were tested at a variety of temperatures and times in both mechanical and vacuum presses. There were five permanent, four removable, and two reversible HA boards. Four of the boards thumb dented rather easily, four have visible adhesive texture, seven require cooling under weight, six cannot be used for multiple bites, three are warped prior to mounting right from the case, four claim neutral pH, four bond as low as 150ºF, and five at standard 180ºF to 185ºF (spreadsheet 1).

As with the some of the P-S board results (PFM, November 2008, "P-S Adhesive Comparisons"), some of these bonding results were also a little surprising. Though porous paper usually bonds well to all boards, it has greater tear strength with a few. Bainbridge HAF, Bienfang Step 150, Alcan HA Fome-Cor, and Gilman InSite all excellently held polyester encapsulated maps, totally unexpected. Add HartMount to that list for RC photograph bonding. When it comes to lightweight fabrics only HAF, Single Step, Step 150, and HA Fome-Cor held—though not aggressively—with the same being true for both raw and digitally printed canvases (photo 6). Kool Tack was very aggressive sowing tear strength with all light, heavy and coated papers and RC traditional and digital photos, though not for fabrics and canvas.

Photo 6

Photo 6

This digital canvas easily peels from the board leaving an indentation in the adhesive but show no tear strength. It failed the test for canvas bond. To pass tear strength it would have torn a layer of surface paper from the board.

Laser prints—dry toner color copies—and thermal dye based inkjet do not bode well under heat, so dry mounting at any temperature should be avoided. Other digital technologies including dye sublimation, dye transfer, thermal transfer, piezo inkjet, or pigmented thermal inkjet all bonded well.

Final Mount

Matching the HA board to the application is essential to creating an attractive, predictable, and successful long term bond. And purchasing any HA board strictly by price is not the best idea. One must consider the physical characteristics of the board by also examining the product for cleanliness, consistency, adhesive application, time/temperature ratios, and board surface. Some boards may run 10-15% higher than others, but there is usually a reason.

If your clientele is all original art and valued collectables then a reversible board might be best. test the players then make your choice. If you run a production operation where cost is a major issue, but time is of the essence, then a basic clay coat with permanent adhesive HA board may be perfect. If you need to accommodate for long digitals by mounting with multiple bites, that too narrows down the selection. Bottom line, know what you need then research the products. The sources are out there, I run these tests so you don't have to. Hopefully we make a great team.

END

Copyright © 2009 Chris A Paschke

For more articles on mounting basics look under the mounting section in Articles by Subject.

Additional information on all types of mounting is found in:

The Mounting and Laminating Handbook, Second Edition, 2002,

The Mounting And Laminating Handbook, Third Edition, 2008 and

Creative Mounting, Wrapping, And Laminating, 2000 will teach you everything you need to know about getting the most from your dry mount equipment and materials as an innovative frame designer.

All books are available from Designs Ink Publishing through this website.

Chris A Paschke, CPF GCF

Designs Ink

Designs Ink Publishing

785 Tucker Road, Suite G-183

Tehachapi, CA 93561

P 661-821-2188

chris@designsinkart.com