The mystery of adhesives in many cases is more of a fear of the unknown. Over the past ten years, I've observed many new products, new companies, and numerous versions of established products reemerge as new. Many times these are developed to help expedite our jobs and just make life simpler. The best way to keep up with the new products and their applications is to be familiar with them. That means read and test.

The computer industry has been both a blessing and a beast. It has simplified our lives by making sales, marketing, and pricing, more quick and efficient, but has also given us the headaches of digital papers and inks we know not how to handle. What's a framer to do?

Even if you understand ALL the adhesives and are comfortable with ALL the techniques what should you do with the project you are unfamiliar with? In some cases even testing it can damage it. When insecure about the item to be mounted, it is usually best to hinge or apply some approved noninvasive conservation technique. All other forms of mounting require an absorption, moisture or heat that may effect the unknown inkjet, vellum project, or whatever.

The Science of Adhesives

An adhesive is a substance capable of holding two surfaces together in a strong bond. This close bond is between the surface molecules of the material being adhered and the substrate. The closer the two surfaces fit together, the stronger the bond. Therefore a thin adhesive bond is often stronger than a thick one.

Two main adhesive types are natural, substances coming from animal and vegetable sources; and synthetic, being compounded from simple chemicals, many of which are polymers. Vegetable glues come from starches and dextrins extracted from corn, potatoes, rice or wheat. Natural gums, although vegetable in nature, are often blended with synthetic rubbers to create adhesives often used in pressure-sensitive cellophane and masking tapes.

Synthetic adhesives fall into two categories: thermoplastic and thermosetting. Thermoplastic adhesives can be resoftened any number of times by reapplying heat and will once again adhere and bond when cooled. They are also soluble in selected solvents. Natural adhesives are predominantly thermoplastic, the most widely used being vinyl resin adhesives, more commonly known polyvinyl acetate (PVA) or white glue.

Thermosetting adhesives undergo an irreversible chemical change when they harden, the result of a catalyst. Once hard, they do not melt or resoften when heated and are considered insoluble in common solvents. Thermosetting adhesives include epoxies, polyesters, and urethanes such as used with fiberglass. These adhesives adhere well to most materials, porous and nonporous.

Framing Adhesives

Thermoplastic adhesives are generally the ones found in picture framing. These adhesives used in mounting artwork to substrates include wet, spray, pressure-sensitive and heat-activated materials. The natural or synthetic base of an adhesive will categorize and in turn determine its appropriateness for any given type of mounting. Some adapt best to mass production, where speed and permanence is desired, while others allow for specialized attention during a slower mounting process.

Wet Glues

Thermoplastic in nature, wet glues are water-based adhesives that include, vegetable starch and PVA. Nonremovable polyvinyl acetate glues (PVA) are water-soluble when wet, but like any acrylic are quite permanent once dry. Wet glues are bottled liquids that are applied to a substrate with a brush, rubber roller, or airbrush. They require the pressure of a weight or cold vacuum frame to create the initial bond, which will hold for an indefinite period. Vegetable starch glues remain removable with distilled water even after long-term mounting.

Sprays

These are air-drying adhesives that are generally thermoplastics. They convert to a solid state by evaporation of the solvent, and bond by mechanical adhesion (the adhesive strength given by interlocking molecules) and mutual attraction. Sprays are packaged in aerosol cans and require proper application and sufficient pressure to create an adequate bond, see May 1998, "Spray Adhesives". Since partial adhesive saturation is required to ensure the best bond, when mounting some high gloss papers, RC photos and polyester fabrics, a truly permanent bond is difficult to achieve.

Pressure-Sensitives

These are predominantly thermoplastics, and require no moisture or heat prior for application. Pressure-sensitive adhesives are available in rolls, precut sheets and premounted to various substrates with release liners applied to protect them from bonding until desired to do so. The adhesive has a release paper backing, is tacky to the touch, and best results are derived from direct pressure of a roller press, squeegee applicator, or weighting during the specified bonding period.

Heat Activated Adhesives

Dry mounting adhesives are easiest to understand when broken into and defined as specific categories. By taking the time to analyze the various available tissues, you will be better prepared to select the proper adhesive to fit your needs. All heat-activated adhesives may be placed into specific categories of:

Type of Bond (Permanent or Removable)

One of the keys to successful dry mounting is remembering where the bonding actually occurs. A permanent adhesive bonds within the press. All layers of the mounting package (top release material, art, adhesive, substrate and bottom release material) must reach the required bonding temperature and remain there during the required time allotment to set the adhesives. When removed they will be bonded.

A removable adhesive bonds once removed from the press as it cools under a weight. It becomes removable through the reapplication of heat, which reactivates the adhesive, making the art separable from the mounting substrate. All mounted items should be placed under a weight when removed from the press, regardless of whether permanent or removable, to expedite the cooling and help reflatten bowed substrates. This weighting step remains the suggested procedure regardless of where the adhesive bond occurs.

Physical Composition (Tissue or Film)

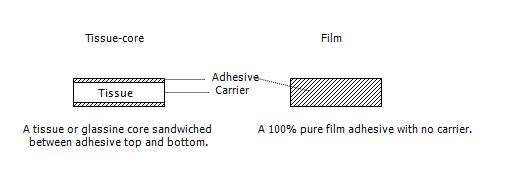

Dry mount adhesives are available in both roll and precut sheets, and come in two basic compositions; tissue-core, and film. Tissues have a center core or carrier of either porous tissue (ColorMount , TM-2 , Trimount , "Super" Unimount , Promount...) or nonporous glassine-type sheet (MT-5, TM-1, Postermount...), with adhesive applied to either side of the carrier for mounting.

Since both sides are identical, there is no top or bottom. They are clean, dry, nontacky , relatively opaque white in color, and are extremely time effective for production use. Tissues adapt extremely well to oversized mountings, float mounting or multiple bite procedures. Pure film adhesives (Fusion 4000, TM-3, Flobond, Acid-Free Mounting Film, Versamount...) are 100% adhesive with no carrier or tissue in the center. This makes them translucent when unmounted and clear when mounted. Some brands of film may be pieced or overlapped because of the lack of central carrier paper, which allows for greater use of scraps.

Degree of Porosity (Breathable or Nonbreathable)

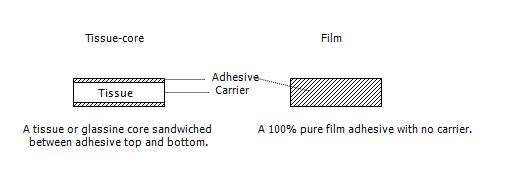

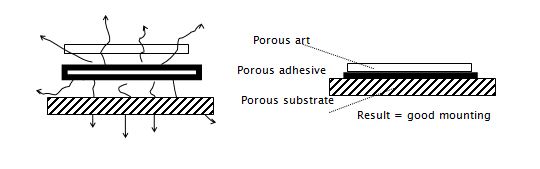

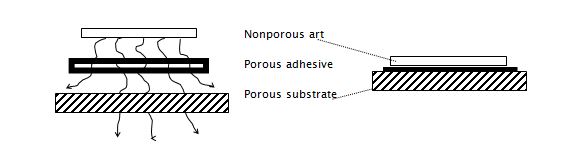

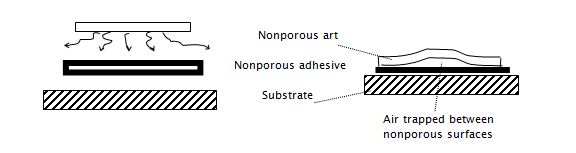

Porosity is the level of which an adhesive is permeable by moisture or air. This is an extremely important designation when selecting a tissue for compatibility with all selected mounting materials. If a nonporous/nonbreathable material, such as a photograph or heavily lacquered print is to be mounted, the adhesive must remain breathable to allow for air or steam to be forced out and/or through the mounting layers. If this is not allowed the project can suffocate.

By using a nonbreathable adhesive with a nonbreathable photo, there is much greater potential for air to be trapped between the two nonporous items creating bubbles in the completed mounting.

If a breathable item is to be mounted to a breathable substrate, essentially any tissue may be used to mount it simply because air will always be able to be compressed out through and around the porous art and substrate.

In any mounting or laminating package, only one layer within the sandwich between release materials on top and bottom may be nonporous. If two exist, such as photo and adhesive, or photo and nonperforated laminate, air is likely to remain trapped between the layers in the completed mounting. In other words, the project will suffocate. Only one layer in any mounting or laminating package may be nonporous, all others must be allowed to breathe.

NOTE: The technique of perforating a nonporous laminate temporarily allows it the porosity necessary to be used over a nonbreathable photo. This prevents two-layer suffocation.

Acidity Level or pH

Since most dry mount adhesives are inert, meaning they are incapable of stimulating a chemical or molecular reaction, it is actually the carrier sheet that needs to be checked for pH levels. Many manufacturers have developed tissues using acid-free or archival carrier papers in conjunction with dry mounting adhesives and have named them accordingly. These tissues mount at lower temperatures, are breathable, removable and neutral pH. They are considered more delicate, but do not meet conservation standards.

Using heat activated adhesives can never be considered archival because the very act of dry mounting art to a substrate breaks all conservation guidelines. Adhesives travel toward the heat as they are mounted, and the very act of dry mounting encourages a certain percentage of nonreversible adhesive to penetrate the back of the artwork, even with a removable tissue.

NOTE: Dry mount adhesives are available from a number of manufacturers and distributors as both name brands and private label brands. Adhesive prices do reflect the thickness of tissues and the amount of applied adhesive per side, so price comparisons need to reflect an understanding of variations in the physical nature of the products.

The 80/20 Rule

There is a theorem, or standard, found within the framing industry called the 80/20 rule. It states that regardless of your choice of mounting method of wet, spray, pressure-sensitive (all considered cold) mounting, and dry (heat) mounting, there will be one basic process used for mounting 80% of the items to be mounted. The remaining 20% of the projects will require an alternative method of mounting. This may be the result of a heat sensitivity, conservation requirement, or simply not being certain of the mounting tolerances in the first place.

This 80/20 concept is applicable to both the overall mounting process as well as the two basic brands of adhesives used within that process. For example, your 80/20 process may be dry mounting/hinging; while your 80/20 dry mount adhesives may be permanent tissue/removable film. It doesn't appear to be the 80% of the mounting that gives us the headaches, it's the 20% of those unknown or unusual projects that does. Pay attention to TTPM and be able to identify when a project is mounting worthy or not.

Mounting has always been the scariest part of framing, even for me. Though I may tell you how to use adhesives, I'm not going to tell you what to use or when, there are too many variables. I will say however, think ahead, mount defensively, and always remember "what if it doesn't act as I expect, when mounted?" That way you may be able to prevent problems. By better understanding the make-up and application of adhesives you should be better armed to select the proper combination of materials to know what to do.

END

Copyright © 1998 Chris A Paschke

For more articles on mounting basics look under the mounting section in Articles by Subject.

Additional information on all types of mounting is found in:

The Mounting and Laminating Handbook, Second Edition, 2002,

The Mounting And Laminating Handbook, Third Edition, 2008 and

Creative Mounting, Wrapping, And Laminating, 2000 will teach you everything you need to know about getting the most from your dry mount equipment and materials as an innovative frame designer.

All books are available from Designs Ink Publishing through this website.

Chris A Paschke, CPF GCF

Designs Ink

Designs Ink Publishing

785 Tucker Road, Suite G-183

Tehachapi, CA 93561

P 661-821-2188

chris@designsinkart.com