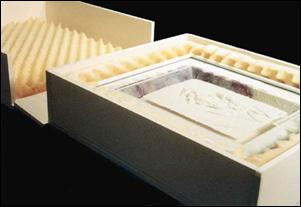

Photo 1

Photo 1

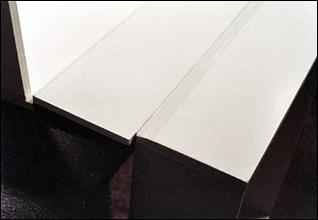

Simple hinge box has single wall construction with hinged top. All sides are lined with eggcrate.

Galleries are frequently in the business of selling, delivering and installing framed art, but on occasion shipping might also be required. A recent art sale of mine required the framing and shipping of eight original paintings to Chicago, IL from Southern California. There are a great many uses for well constructed reusable boxes and this is often a service overlooked by framers. Artists often require their framed art to be shipped from place to place for exhibition, then returned home safely if not sold, and sometimes juried exhibitions won't accept art shipped in bubble wrap, loose pellets or shredded paper because of the mess refusing to unpack or exhibit pieces that arrive with labor intensive or messy packing materials. Though loads of bubble wrap and foam pellets may indeed protect glazed art from damage, but is a major annoyance for the receiving department or museum curator.

Shipping Requirements

The meeting of shipping requirements for framed art may vary slightly in different counties but the basic guidelines remain consistent. Local shipping companies such as UPS (United Postal Service) or FedEx have very specific guidelines any shipper must meet in order for an insurance claim to be honored if damage or loss occurs. Though they both frown on shipping glassed art over 8"x10", if proper precautions are taken and the item is packed according to their guidelines they will ship larger framed pieces. Basic packing procedures include taping the glass to prevent additional damage to art if glass is broken or shattered, and 2-4" of cushion surrounding all sides, top, bottom and corners. Beyond this—always pad so the box would protect its contents if dropped or thrown a full ten feet. Though this sounds aggressive it is a fact that boxes are stacked up to ten feet high for carrier transport and once they arrive to the transition points those stacks are simply pushed over to get to the top boxes.

The external box may be corrugated, foam center board or wood. Internal requirements include 3-4" of padding all six sides; crisscrossed tape or Glas-Skin applied to glazing; and corners reinforced with corrugated wraps or pads. If shipping in corrugated boxes the sealing tape should be a minimum of 2" wide for light packages or 3" wide 60# water-activated tape for heavier packages and applied in the H-pattern across seam closure and along the ends on both sides. Tapes should be acrylic or clear pressure-sensitive packaging tapes and need to be burnished to activate the adhesive for a secure bond. Never use duct tape, Kraft paper tape, masking tape, or string to seal the box. Labels should be placed on the largest side, upper right, a few inches in from the edge. It's also a good idea to place shipping and receiving information inside the box—just in case of damage.

Loose pellets, flo-pak peanuts, bubble wrap and thin polyethylene foam sheets may be fine for shipping some things but are not advised for padding picture frames. Inflatable air fill packaging is also not advised as the inner air inflation is effected by both altitude and temperature. If they further inflate additional pressure could cause damage and deflation can allow frames to move around. Crumpled Kraft paper works as padding when a box is packed within another box but not for art, and expanded polystyrene foam (EPS) sheets are too solid to cushion art allowing for package concussion to transfer inside to the frame.

The best padding around a glassed frame is convoluted acoustic eggcrate foam—called egg box foam (UK)— which is sold in 1½" and 2½" thicknesses in sheets and tiles. The thicker foam has a 45# compression making it soft yet firm buffer to exterior concussion. Grey square acoustic egg box tiles are available UK 73mm thick, which can easily be pieced together as needed.

Commercial Boxes

There are numerous companies who specialize in building reinforced corrugated shipping boxes with sponge eggcrate foam lining for artwork. Commercial boxes are generally clamshell construction with double wall options. They vary in size to accommodate most framed pieces and may be used more than once. Airfloat and Uline foam lined shipping boxes can run USD $40 to $100 depending on the size and number of boxes purchased at a time.

The down side of using commercial boxes is they do not allow for more than 2" foam pad surrounding the frame with most supplying only 1" 1½" of eggcrate foam, and although box strength is good, the padding is not. PackaFrame and CanvasPak shipping boxes, UK—like AirFloat Systems, USA—are economy alternatives to building a foam box.

In-House Boxes

Building boxes in-house allows for custom fitting and better frame cradling for shipping. Foam center board is perfect for box building because it is easy to cut, the foam insulates the art from both hot and cold, and may be purchased from most frame suppliers. Gatorboard is not recommended for boxes because the rigid veneer surface allows for puncture holes and cracking, while ½" foam center board does not crack it only depresses and dents making it another form of cushion from impact. If ½" foam is not available double 3/16" may be substituted, but these sheets need to be adhered together with two-sided tape or hot glue.

Photo 1

Photo 1

Simple hinge box has single wall construction with hinged top. All sides are lined with eggcrate.

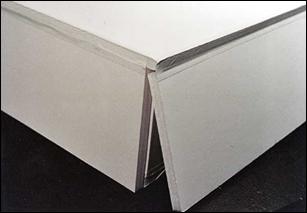

Photo 2

Photo 2

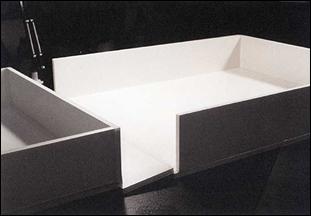

Clamshell box to fit frame w/sponge padding and lift blocks attached to heavy corrugate.

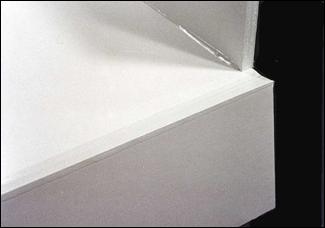

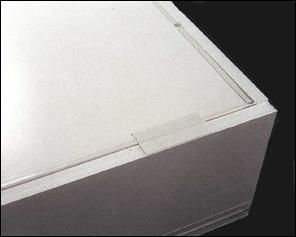

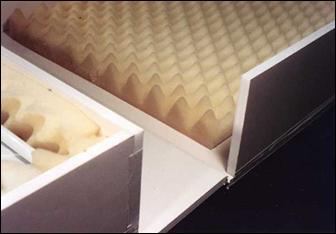

There are numerous box types that all service specific needs, but all should be fully lined with 2½" eggcrate foam. The simple hinged box is the most common, built for one time shipping, though is sturdy enough for long term storage and reshipping. It is a single wall base with the lid book hinged on the longest side (photo 1). The clamshell box is hinged along the short side to the lid which becomes a double wall box once closed (photo 2). Note the sample photo shows an oversized box where the top and bottom eggcrate sponge was substituted for a double thick corrugated sheet with dense 3" blocks of acoustic sponge foam for cushioning. The double wall box has a base and lid that fit together like a shoebox creating a box within a box making it strong for heavier or multiple frame shipping (photo 3). The drop spine box is a double wall construction where the lid remains attached to the base at all times like the clamshell box, but may be opened to lie flat for packing (photo 4). Drop spine and simple hinged are the two most often built by me. In fact the eight framed pieces shipped to Chicago were sent in three shipping boxes, with multiple frames of the same size in each. In this case each frame was spaced with another full sheet of 2½" foam. The boxes were lightweight, yet durable and arrived in perfect shape via FedEx ground.

Photo 3

Photo 3

Double wall box uses ½" foam for box bottom and lid that fully fit together like a shoe-box.

Photo 4

Photo 4

Drop spine box lined with eggcrate foam all sides.

Simple Hinge Box Construction

This is the most popular and common box for shipping because of the speed and ease to create. Measure the completed frame then add 6" to length and width for top and bottom box dimensions, then cut two pieces from ½" foam center board. For height of sides, measure frame thickness and add 5" for addition of 2½" eggcrate sponge and cut two sides the height measurement by the length of the bottom, and two sides the same height by the width of the bottom. Since the box sides are butt joined the two shortest pieces need to be trimmed 1" shorter to fit inside the perimeter of the box bottom.

Double Wall Construction

The basics are the same for a double wall construction box as above, but the lid must be sized to slide over the walls of the bottom box thus creating a double insulated 1" thick wall. The easiest way to insure correct sizing is to construct the bottom first then the top by measuring the bottom and adding the side wall dimensions. With ½" foam sides the top will be 1" larger than the bottom length and width.

Drop Spine Construction

The reusable drop spine box is a little more work but very user friendly. It is perfect for multiple shippings for artists from exhibition to exhibition as art is well protected and easy to pack, unpack and repack. As with the above double wall box, both the clamshell and drop spine require the same dimension adjustments for the lid to close down over the box base, but a drop spine lid remains hinged to the bottom at all times.

Photo 5

Photo 5

All sides are glued to the base and each other, then a bead of hot glue along each inner seam.

Photo 6

Photo 6

All outside seams are reinforced with 2" wide shipping tape.

Step-by-step

Photo 7

Photo 7

Burnish all applied pressure-sensitive tape with bone to fully activate adhesive.

Photo 8

Photo 8

Burnish all applied pressure-sensitive tape with bone to fully activate adhesive. Fit lid over completed box bottom. Then apply and burnish tape hinge on outer seam of loose panel.

When building the lid one end panel becomes the drop spine hinge and will not be solidly glued to the lid as the other three

Photo 9

Photo 9

Do not glue end panel to the box lid. Hinge the panel to the box lid on inside edge only.

Photo 10

Photo 10

Lift panel and tack with tape to temporarily hold, then tape hinge full seam.

Suspend the box bottom over a table edge to expose the inner seam for easy taping. Align and burnish shipping tape along inner seams (photo 12).

Photo 11

Photo 11

With box flipped over the lid panel should freely swing open.

Photo 12

Photo 12

Lift lid off box bottom and tape hinge inner panel seam.

Once the two box halves are hinged together make certain all seams have been reinforced with one single piece of 2" wide tape the full length of each seam. The assembled box has a solid, reinforced base box unit which has been hinged to the box top using the end of the box as a hinge (photo 13).

Photo 13

Photo 13

Open box shows three sided lid with fourth attached to box bottom.

Photo 14

Photo 14

Size foam to fit inside top and bottom. Score foam back w/sharp blade, then pull apart.

Eggcrate foam is best for padding the inside of the box because of its contoured design. It more readily conforms to the odd shape of frame mouldings and the recessed glazing.

The bottom piece should be cut to fully fit inside the box while the top should be about 2"-3" smaller to accommodate for the side padding and inner box wall when lid is closed.

Line the sides of the box with the same foam for cushioning, and creating a custom cradle for the art and frame.

Photo 15

Photo 15

Glue foam to all sides to hold it in place for ease of art removal.

Photo 16

Photo 16

Sponge is hot glued to box top and bottom and all inner sides.

The completed and lined drop spine lid lays flat for repacking and allows for easy fitting over the bottom unit (photo 16). Note the smaller sponge foam fitting into the lid.

By hot gluing the drop spine hinge panel to the corresponding bottom box side the hinged lid turns into a clamshell design where the lid has three sides with the fourth fused to the bottom. The lid then lifts off the bottom but remains attached.

Final Thoughts

Building reusable shipping boxes are a viable market but will need to be sold like any new service. List them on your website, talk with art guilds and photo groups in your area, if artwork is being sent to shows, and make a small 8x10" sales tool (photo 1) as a sample. Like installation, you might even create a whole new revenue source.

END

Copyright © 2013 Chris A Paschke

Shipping Links

In-House Shippers and materials:

UPS = www.ups.com

UPS UK "packaging" = www.ups.com/packaging/guidelines?loc=en_GB

FedEx UK = www.fedex.com/gb

FedEx = www.FedEx.com, "How to Pack"

The Foam Factory = www.thefoamfactory.com

eFoam = www.efoam.co.uk

Easy Foam = www.easyfoam.co.uk

Glas-skin = http://www.airfloatsys.com

Commercial Art Shippers crate, store and ship:

PackaFrame = http://www.packaframe.co.uk

AirFloat Systems, Inc = http://www.airfloatsys.com

Online Boxes UK = http://www.onlineboxes.co.uk

Pack & Send UK = http://www.packsend.co.uk

Constantine = http://www.const.co.uk

HMC Packing = http://www.hmcpacking.com

Additional Reading and References

Creative Mounting, Wrapping And Laminating, Chris A Paschke, CPC GCF, "Shipping Boxes", pages 84-89.

—"Drop Spine Shipping Box", http://www.designsinkart.com/library/B-DropSpineShippingBox199511.htm

—"Shipping & Bond Failure", http://www.designsinkart.com/library/B-ShippingAndBondFailure201006.htm

—"Flat Shipping Boxes", http://www.designsinkart.com/library/B-FlatShippingBoxes199512.htm

For more articles on mounting basics look under the mounting section in Articles by Subject.

Additional information on all types of mounting is found in:

The Mounting and Laminating Handbook, Second Edition, 2002,

The Mounting And Laminating Handbook, Third Edition, 2008 and

Creative Mounting, Wrapping, And Laminating, 2000 will teach you everything you need to know about getting the most from your dry mount equipment and materials as an innovative frame designer.

All books are available from Designs Ink Publishing through this website.

Chris A Paschke, CPF GCF

Designs Ink

Designs Ink Publishing

785 Tucker Road, Suite G-183

Tehachapi, CA 93561

P 661-821-2188

chris@designsinkart.com