Photo 1

Photo 1

U-shaped spring clips made of spring steel.

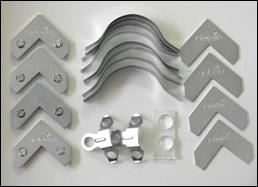

A spring clip for a metal frame is a U-shaped metal band made of spring steel used to retain artwork in sectional metal frames (photo 1). They are most often sold as part of the hardware package (photo 2) that comes with sectional frames and are designed for filling the extra space between the art panel or mat package and the back of the frame (photo 3). They are easy to install, reusable, and fill a range of voids.

Photo 1

Photo 1

U-shaped spring clips made of spring steel.

Photo 2

Photo 2

Hardware package for sectional metal frame.

Though they are commonly used by artists and economy framers alike there is a problem that can occur from their use and should not be used when framing original art or preservation quality framing. The very pressure that holds the backing boards and glass or wood panels against the front lip of the frame is same thing that create unfavorable pressure points along the perimeters of the art. The strength of the clip can indent foam center board at the pressure points around the frame as seen in photo 4. Foam center board absorbs the compression damage of the indentations but mat boards do not and in humid environments the areas that have no pressure can absorb moisture and warp between the spring clips. This is damage that cannot be reversed as once paper fibers have swollen by moisture that will never dry out and retract to their original size. A warped mat will need to be full replaced.

Photo 3

Photo 3

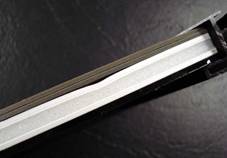

Spring clip applies pressure between back lip of frame and mat or painted panel.

Photo 4

Photo 4

The small indent shows the pressure point that compressed the foam board.

Once spring clips are removed from a frame the fit space is evident when pressing the package to the front of the frame (photo 5). The best way to avoid pressure point damage is to eliminate the pressure points by cutting same size filler boards from scuffed or surface damaged, unusable mat blanks or foam center board. The fit space in the sample frame allows for two faded 4-ply mat blanks to be cut to size and slipped into the metal frame channel (see photo 4). The front of the completed frame is flush against the front lip—as it should be—and the back of the finished frame is clean and ready for wiring and signature (photo 6).

Photo 5

Photo 5

(front to back) Glass, mat package and open fill space. Two 4-ply mat blanks fit the space as filler (see photo 4).

Photo 6

Photo 6

Finished, wired frame ready to hang

Like many 'quick fix' concepts, spring clips are convenient and easy to use but do indeed have their drawbacks. Artist beware.

END

Copyright © 2012 Chris A Paschke

For more articles on mounting basics look under the mounting section in Articles by Subject.

There is a special section in the library for all past IEA Framing Matters articles from Wax-On!

Additional information on all types of mounting is found in:

The Mounting and Laminating Handbook, Second Edition, 2002,

The Mounting And Laminating Handbook, Third Edition, 2008 and

Creative Mounting, Wrapping, And Laminating, 2000 will teach you everything you need to know about getting the most from your dry mount equipment and materials as an innovative frame designer.

All books are available from Designs Ink Publishing through this website.

Chris A Paschke, CPF GCF

Designs Ink

Designs Ink Publishing

785 Tucker Road, Suite G-183

Tehachapi, CA 93561

P 661-821-2188

chris@designsinkart.com