Paschke Online

Designs Ink Publishing Article Archive and Reference Library

Articles by Chris A. Paschke, CPF GCF

"Informed Adhesive Selection"

April 2020

Custom framing routinely replaces older techniques with new products and new technology; and adhesive demands have gone way beyond the requirements of mounting only the paper, photographs and canvases of the past. It is the job of the today's framer to select the best materials and adhesives for what is being framed while always being mindful of not enclosing untested products from other industries within any frame. It's more than simply finding an adhesive that will bond layers together; framing adhesives also need to have been time tested for long term bond, absorption, seepage, stability, and inertness, let's review.

Natural vs Synthetic

Adhesives are either natural or produced synthetically, and are categorized by their method of adhesion. Natural adhesives are made from organic sources such as vegetable starch, natural resin, or animals (hide glue and milk protein casein). Vegetable glues come from starches and dextrins extracted from corn, potatoes, rice, or wheat and may be used in the production of corrugated board, paper bags, and wallpaper adhesives. Natural gums are often blended with synthetic rubbers to create adhesives sometimes used in pressure-sensitive cellophane and masking tapes. Animal glues have traditionally been used in bookbinding, wood joining, and plywood but now use of these is being replaced by synthetics. Synthetic adhesives are reactive—referring to an adhesive that must chemically reacts in order to harden—or non-reactive—as those that do not, and are divided into two categories: thermoplastic and thermosetting.

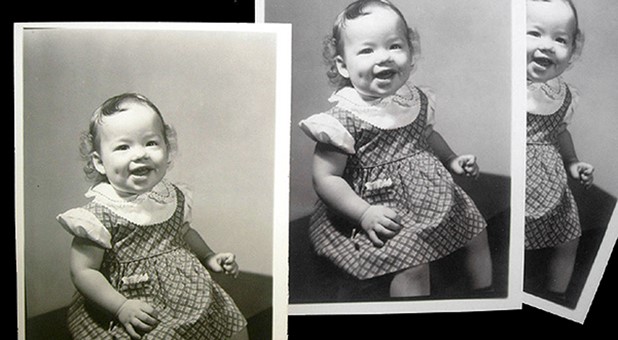

Thermoplastic adhesives are heat set and may be softened numerous times by the reapplication of heat, once again adhering once cooled. In framing these are called removable dry mount tissues, films, and HA boards. Natural adhesives are predominantly thermoplastic; the most widely used being polyvinyl acetate (PVA), also called white glue, which is flexible, strong and non-acidic. (photo 1)

Photo 1

Photo 1

PSAs are permanently tacky thermoplastic adhesive that bonds to an untreated surface at room temperature with the application of pressure. Kooltack's InstaMount S-A boards are available on Competition Plate, Gatorboard, Mighty Tough and Foam.

Thermosetting adhesives undergo an irreversible chemical change when they harden, the result of a catalyst. Once hard, they do not melt or resoften when heated and are considered insoluble in common solvents. Thermosetting adhesives include epoxies, polyesters, and urethanes such as used with fiberglass. These adhesives adhere well to most materials, porous and nonporous, and include epoxy, polyurethane, cyanoacrylate and acrylic polymers.

Adhesives used in mounting artwork to substrates include wet, spray, pressure-sensitive and dry heat activated materials. The natural or synthetic base of an adhesive will categorize and in turn determine its appropriateness for any given type of mounting.

Dry Mount

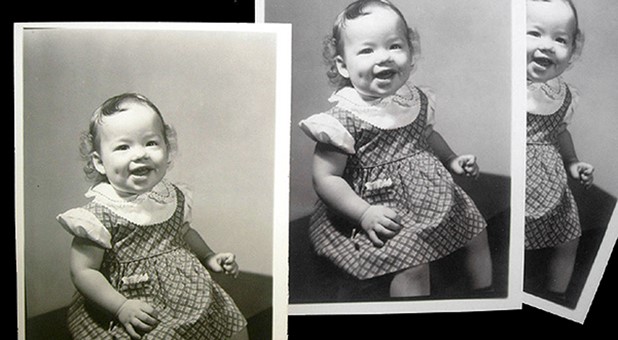

Dry mounting may seem to be somewhat a thing of the past, but it's rather a much more sophisticated process with many more solutions that ever before. Permanent tissues, higher temperature HA boards (160-185°F), and high tack pressure-sensitive boards adapt best to mass production where speed and permanence is desired. Removable tissues/films and thermoplastic lower temperature HA boards (150-175°F) might be best for replaceable art and duplicates for display. Permanent adhesives may be released from the substrate with assorted chemical solvents and removable adhesives require reapplication of heat for removal, but in both cases there shall always be adhesive residue remaining in the art that renders it non archival. (photo 2)

Photo 2

Photo 2

The original heat tolerant fiber base studio portrait circa 1953 (left) would easily mount using any permanent or removable tissue up to 190°F. The dye sublimation copies (right) show a thinner, cooler image that would tolerate lower heat, but would also be susceptible to orange peel.

Reversible HA boards (150-160°F) are perfect for items previously unsuitable for dry mounting that were always reserved for preservation techniques only. These boards allow the art or collectible to be brought fully back to its original state once removed with no adhesive residue, making them reversible and archival.

Rolled Tissue Categories

All heat activated adhesives may be placed into these specific groupings: type of bond (permanent or removable); physical composition (tissue-core or film); porosity (breathable or non-breathable); and acidity/pH (unbuffered, buffered or rag carrier). Once these four things are noted, all generic and manufacturer products are easily compared for use.

Type of bond dictates the mounting technique to achieve the proper bond and where that bond happens. A permanent adhesive bonds in the press as all layers reach adhesive activation temperature and the permanent bond is created. Removable adhesives melt as all layers reach activation temperature, but the bond is not made until the mount is removed from the press and cooled under an even weight. This remains true whether mounting with tissue/film and substrate of choice or HA board, but all mounted items show always be cooled under an even weight, even if only for 30 seconds.

Always pay attention to the four elements of mounting: time, temperature, pressure, moisture (TTPM). Set the proper temperature; keep the mount in the press long enough for all the layers to reach that temperature; make sure the pressure is set for the thickness of the substrate; and pre-dry art and substrate for 30 seconds—between Kraft paper sheets—prior to bonding in any mechanical press. A vacuum press automatically handles both pressure and pre-drying.

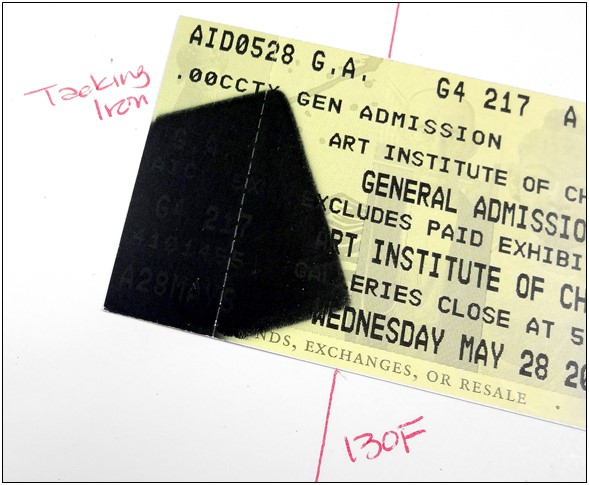

Adhesives for Digitals

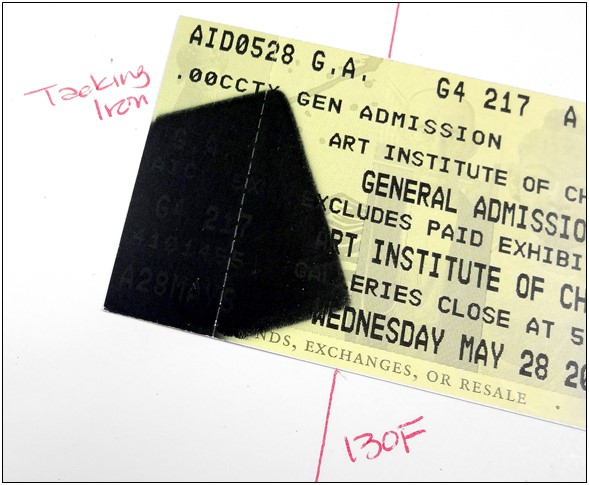

There is also a category of permanent, low temperature HA boards (130°F) developed specifically for the digital age, and is safe for ALL digitals. (photo 3) Some heat sensitive digitals tolerate up to 150°F as long as the duration under the heat is limited to less than 30 seconds, but any longer can damage the surface image, so they bond in a mechanical press but images may not tolerate the 4 minute dwell time of a hot vacuum press.

Photo 3

Photo 3

Right half of thermographic dry toner color copy was mounted at 130°F showing no damage while left side of ticket was damaged by the heel of a 180°F tacking iron.

Some digitals tolerate any temperature because their inks are not affected by heat, but some newer digital photo papers and all laser toner B&W and color copies are impacted by heat. MountCor boards—for digital photos, paper and canvas—are permanent and low temperature. Digitals are unaffected by this low temperature for any length of time allowing them to be mounted in hot vacuum presses that the 150°F boards and tissues cannot offer.

Digitals today cover a greater number of technologies and materials than ever before and it is becoming increasingly difficult to identify the source of an image, making it difficult to know whether an ink or printed image will be heat sensitive of not. And since digital images are considered prints and not originals and therefore replaceable, between low temperature HA dry mount boards and high tack pressure-sensitive mounting with rollers, permanent bonding of digitals has become commonplace.

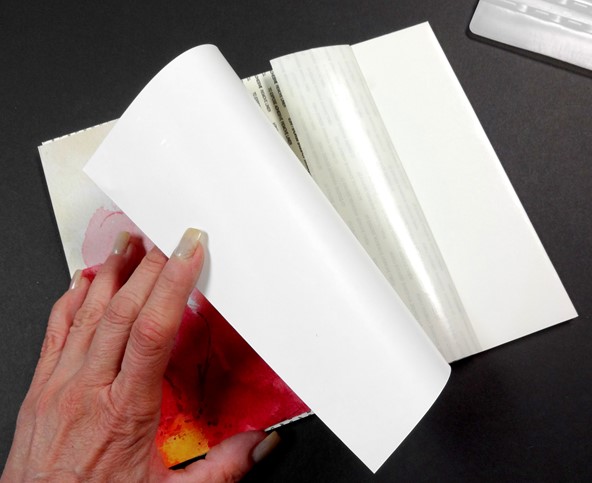

P-S Types and Tack

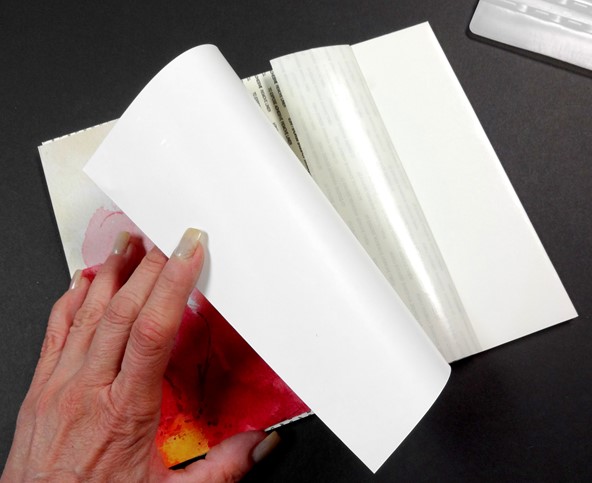

Pressure-sensitive adhesive (PSA or P-S) is a permanently tacky thermoplastic substance that bonds to an untreated surface at room temperature with the application of pressure. They are dry, synthetic adhesives that are clean, easy to use, odorless, and require no heat or solvents. They are available as both films—to be applied to any substrate of choice—and with the PSA applied to a substrate, also called self-adhesive (SA) board. (photo 4)

Photo 4

Photo 4

Peel back top edge to expose adhesive; align print at bottom corners; follow-up with fingers from bottom and press against exposed adhesive; pull liner from beneath print and smooth from top to bottom to prevent bubbles; cover with liner and press, roll, or burnish to activate.

High tack (HT) PSA is aggressive and most difficult to hand apply to large images since it is not repositionable and is often recommended for use with roller machines. They immediately grab to a smooth nonporous item, like a photo or clay coated foam board, and may not be repositioned. Though somewhat lacking in long term bond, medium and low tack PSAs are the ones most frequently favored in picture framing. They may be somewhat repositionable during mounting with porous papers, but even repositionable self-adhesive boards will grab more aggressively to a smooth or coated material. Low tack (LT) is not well suited to the longevity of framing demands, and is least favorable on self-adhesive boards for framed display art. (photo 5)

Photo 5

Photo 5

(L-R) Gilman LT, Gilman HT, Alcan LT, Alcan HT, HarTac, Elmer's/Encore Permanent, United Industries, Coda 3/16", Coda 1/4", and Bainbridge Foam. Not shown: Crescent PerfectMount film and boards, D&K, Drytac.

Bond strength—or tear strength—is a better phrase than permanence when referring to adhesives because of the subjectivity of what might be meant by permanent. In the case of a PSA, permanent means impossible to remove without destruction of the substrate or mounting. A removable PSA may be removed without harming the substrate in any way or leaving adhesive residue, like a post-it-note. The act of permanently bonding any art to a backing is never a preservation method. Remember...regardless of how stable and inert any adhesive may be, it is the adhesive absorption into the art that makes a mounting method non-reversible and non-preservation.

Final Mount

Sometimes sticking with industry standards can be a good thing, but remember that the techniques and products mentioned here are not meant to dismiss contemporary preservation techniques. It seems that there are currently two large groups of common items being framed...digitals and valued collectibles. Original art and irreplaceable items will always require reversible mounts and preservation mounting techniques, while digitals are replaceable. In today's world, open edition prints...are digital; printed canvases are digital; magazines and periodicals are digital; photos are digital. The digital umbrella has expanded so far that it has touched every printing process including the wrapping of cars and buildings. (diagram 1)

Diagram 1

Diagram 1

Digitally printed images are now on Yupo, Tyvek, Evolon, fine art paper, metal plate, acrylic, sheer fabrics, canvas and more, and often those images require adhesives and mounting substrates to display them, which could include Dibond (ACM), honeycomb panels, Gatorboard, hardboard, cradled boxes, Sintra, and more we haven't even heard of yet.

Mounting in this decade is not your grandfather's mounting, yet many practices and adhesives are tried and true. Products have improved but often techniques remain the same. Never throw out the baby with the bathwater, while still keeping open to improvements.

END

Copyright © 2020 Chris A Paschke

Resources

https://en.wikipedia.org/wiki/Adhesive

https://www.designsinkart.com/articles-subject.shtml—(see "Adhesives", "Digitals", and "Mounting" sections)

For more articles on mounting basics look under the mounting section in Articles by Subject.

Additional information on all types of mounting is found in:

The Mounting and Laminating Handbook, Second Edition, 2002,

The Mounting And Laminating Handbook, Third Edition, 2008 and

Creative Mounting, Wrapping, And Laminating, 2000 will teach you everything you need to know about getting the most from your dry mount equipment and materials as an innovative frame designer.

All books are available from Designs Ink Publishing through this website.

Chris A Paschke, CPF GCF

Designs Ink

Designs Ink Publishing

785 Tucker Road, Suite G-183

Tehachapi, CA 93561

P 661-821-2188

chris@designsinkart.com

Photo 1

Photo 1 Photo 2

Photo 2 Photo 3

Photo 3 Photo 4

Photo 4 Photo 5

Photo 5 Diagram 1

Diagram 1