Paschke Online

Designs Ink Publishing Article Archive and Reference Library

Articles by Chris A. Paschke, CPF GCF

"Mounting Digital Papers"

February 2006

In order to select the proper mounting technique for any given digital image you must first get to know up close and personal. Today's 21st century framer needs a more comprehensive understanding and working knowledge of the composition of printing papers, their coatings, and the behavior of inks printed on these papers in order to make the correct decisions about how to mount them. Up until now, heat sensitivities of digital inks have been linked to thermal dye base inkjet printers. But recent scientific and use tests have begun to show it is more likely a paper coating issue and not a technology issue after all.

The Mounting Debate

During the last few years Digital Fine Art (DFA), digital canvases, and digital photographs have become common place artwork for custom framing. Though it is true most any image may be preservationally mounted using hinges, corner pockets, or edge strips, more times than not, a digital photo or canvas may actually look better when mounted to a rigid substrate. Poster images, open editions, on-demand inkjet prints, canvases, and LE giclees will always be around, and the question of whether or not to mount them as fine art will no doubt be debated for years to come.

Digital Compared to Traditional

I have been teaching about digital printing technologies in relation to framing and mounting for ten years now, and little by little we seem to have a better understanding of them. When properly printed and stored, dye-based inkjet and dye diffusion thermal transfer prints have light stability equal to traditional photographic C-prints (chromogenic, RC). And over time color toner electrophotographic and even pigment based inkjet prints have become more stable. This all makes the framing and display of digital fine art and photos much more viable, but there still remain issues over heat tolerances when mounting.

New Digital Thinking

Throughout my five year affiliation with the photo and digital International Standards Committees (ISO) we have been working towards developing tests and comparisons to better understand the world of digital imagery. My own private testing for the framing industry began in 1996 (Heat Tolerance Test #1) with a study of heat tolerances of electrophotographic and electrostatic toner copies under dry mount temperatures ("Digital Heat Tolerances", February 2002).

Then in 2000 (Basic Heat Tolerance Test #2) and 2001 (HP Heat Tolerance Test #3) I ran tests using an HPdeskjet 960c printer with assorted papers in an attempt to determine the tolerances of thermal desktop printers with the same mounting adhesives and equipment ("Handling Digital Photos: Heat Testing Part Two", June 2002). The test results indicated that thermal technology, as opposed to piezo inkjet technology, was what allowed for the heat sensitivities when dry mounting. And until recently my ISO scientists seemed to believe and agree with my hypothesis.

During our most recent ISO meeting, September 2005, I was challenged by the group that it is not thermal vs. piezo inkjet technology but rather the paper coatings that may actually be heat sensitive. So in October 2005 NielsenBainbridge agreed to sponsor the fourth in my series of heat tolerance tests, this one to compare Epson piezo inkjet technology, paper coatings, and inks under heat.

Heat Tolerance Test #4 - Epson

Having used a Hewlett-Packard 960c thermal inkjet printer as the control in my test I needed to repeat the same basic test but this time using an Epson c86 piezo inkjet printer. While researching printers I also discovered a line of Epson dye ink printers, so my cover statement that all Epson printers are pigment is wrong.

The new heat sensitivity hypothesis is that swellable coatings are more sensitive to dry mount temperatures than porous ones. So in Test #4, I tested each 8x10" image at multiple temperatures of 150°F, 170°F, 185°F, 200°F, and 225°F with a strip of vinyl laminate (photo 1). The results were way more revealing than originally expected, as I was also able to identify differences in ink saturation, surface durability and reaction to moisture.

Photo 1: Epson Heat Tolerance Test

Photo 1: Epson Heat Tolerance Test

Upper left top three photos are uncoated DFA papers; top center eight are coated DFA papers; upper right seven are swellable; second row from bottom are porous; and bottom row are all porous on resin coated media. Each 8x10" photo has been divided into six strips and tested for heat tolerance at F 150°, 170°, 185°, 200° and laminated at 225°.

Types of Paper

The biggest challenge was going to be identifying the inkjet papers (photo 2). Inkjet papers may be uncoated, or coated with a surface receptor. There are two types of coating: swellable and porous, plus either may be applied to 100% paper base or resin-coated paper base.

Photo 2: DFA and Photo Papers

Photo 2: DFA and Photo Papers

Inkjet papers may be uncoated, or coated with a surface receptor. There are two types of coating: swellable and porous, plus either may be applied to 100% paper base or resin-coated paper base.

Uncoated papers contain a wide range of weights and surface textures. At one end of the uncoated paper spectrum is 20# to 26# lightweight bond paper used as everyday printer paper. The other end is mouldmade, fine art paper such as Arches, Rives BFK, and Somerset. These may also come with different surface finishes including rough, cold-press (CP) and hot press (HP), and most of these work with both thermal and piezo printers using either dye or pigmented inks. Since inks interact directly with the raw paper, uncoated papers soak up the ink rather than being trapped by a coating, making colors generally less vivid and vibrant (photo 3).

Photo 3: Swellable Coated vs. Uncoated DFA

Photo 3: Swellable Coated vs. Uncoated DFA

Left Jetprint Premium Photo, a coated swellable paper. Right is Lanaquarelle HP, and uncoated DFA paper. Since inks interact directly with the raw paper, uncoated papers soak up the ink rather than being trapped by a coating, making colors generally less vivid and vibrant.

Uncoated papers have two components: the base and the sizing. The substrate base constitutes the weight, body, and surface texture of the paper as described above. The sizing may have been added either internally during production or as a surface sealer to control absorption of moisture, such as traditional watercolor papers.

Coated papers may be fine art or photo papers that have been treated with a receptor coating for inkjet printing. The surface coatings may be of many different substances including tiny glass beads, silica, clay, calcium carbonate, or assorted polymers. They are designed to enhance and control the printed image and may alter the base paper surface allowing for a variety of finishes from high gloss to matte.

Coated papers are classified by assorted designations and categories. They are fine art or photo papers; the surface finish is gloss, semigloss, satin, or matte; and the by coating is swellable or porous. These all help to indicate their intended end use.

Swellable (Polymeric, Non-porous)

Swellable coatings are slow dry, moisture and humidity sensitive, relatively lightfast, and resistant to gas fading. They are more photographic, glossy, and better geared to dye based inks, though images may appear more grainy producing a more noticeable dot pattern. Swellable coatings react differently to dye or pigment and in turn colors may vary a great deal in final printed images (photo 4). When a drop of water is placed on the surface it create a slippery film with the wet ink (photo 5).

Photo 4: Color Variations

Photo 4: Color Variations

Center top HP Glossy Premium Photo Paper has a yellow tint; upper right Jetprint Premium Photo Paper has a green tint; lower right Ilford Galerie Classic Gloss is closest to the original photo color; lower left Epson Colorlife Photo appears very green. All swellable, potentially heat sensitive images.

Photo 5: Water on Swellable Coating

Photo 5: Water on Swellable Coating

When a drip of water is placed on the surface , it does not absorb and when rubbed it creates a slippery film removing the ink from the coating.

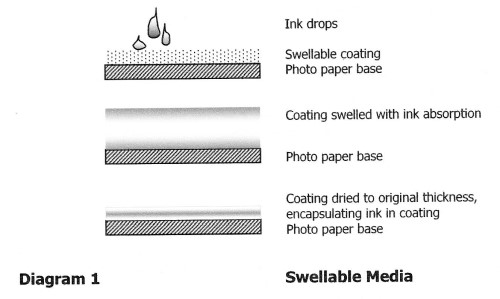

Swellable coatings are made of organic gelatin like polymers that surround and encapsulate the ink when it hits the paper. The coating swells two to three times its original thickness as it absorbs and spreads the applied ink. Once the coating has dried it returns to its original thickness while encapsulating the ink droplets. This is why it takes longer to dry once printed and is what makes them more lightfast than porous coatings (diagram 1). Swellable media (papers) include: HP Premium Plus Colorfast Paper, Epson Colorlife Photo Paper, and Ilford Classic Pearl and Gloss Paper.

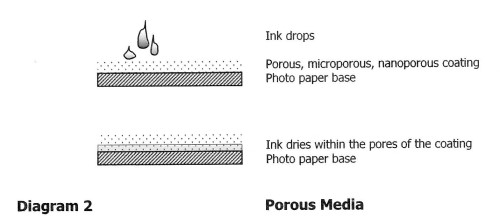

Porous (Microporous, Nanoporous)

Porous coatings are fast drying, moisture resistant, more light sensitive and prone to gas fading, but generally adapt well to printing of both dye and pigment inks. They are more high resolution than swellable coatings, and are marketed as quick or instant dry. When a drop of water is placed on the surface it is absorbed resulting in no major change to the paper (photo 6). Excessive water may cockle the paper with no ink damage, while dye inks may bleed or leave a ring.

Photo 6: Water on Porous Coating

Photo 6: Water on Porous Coating

When a drop of water is placed on the surface it is quickly absorbed resulting in minor surface change to the paper, but papers may cockle. Though it looks like it is swelling it is merely soaking in. The water is puddled on the paper but will dry flat.

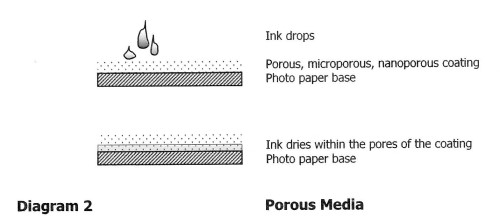

Porous coatings consist of tiny particles glued together with air spaces or 'pores' between them. These pores suck the ink droplets into the open spaces as the water in the ink evaporates (diagram 2). When the ink dries out, an embedded layer of colorant remains in the coating. Swellable coatings encapsulate the ink, while porous coatings spread the ink out evenly over the entire surface within the coating. Porous media include: HP Photo Paper, Epson Premium Glossy Photo Paper, Hahnemuhle Photo Rag, and Crescent Digital Papers.

Microporous papers differ from porous papers in that most have a receptor coating made up of highly uniform ceramic (glass or silica) particles. They create a set of pores that act as inkwells trapping the ink just below the coating surface. Inkwell uniformity makes for quick ink absorption and drying, and unlike the clay coated surface receptors they have better water resistance and less loss of gloss after ink application. They work well for both dye and pigment inks and most microporous papers also use an RC or polyethylene layer behind the coating to eliminate waviness and wrinkles with heavy ink applications.

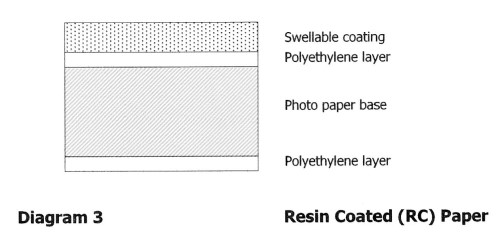

Resin-Coated (RC)

Resin-coated is not really a coating at all, but rather a way in which the paper is constructed. Similar to the standard RC papers familiar with traditional photographs, the same concept is utilized in digital photos. It is basically a paper substrate sandwiched between two layers of polyethylene, with either a swellable or porous receptor coating applied to the top (Diagram 3). These papers easily replicate the look and feel of traditional RC photos. Water droplets have a tendency to sit on the coating surface until the air evaporates it, with no resulting change to the paper once dry (photo 7).

Photo 7: Water on Porous Resin Coated Paper

Photo 7: Water on Porous Resin Coated Paper

Water droplets on coated RC paper will sit on the surface coating until the air evaporates it with no change to the paper once dry. Epson Premium Luster, porous, RC paper.

Matching Inks To Papers

There are two basic categories for inkjet inks: dye and pigment. Dyes have a wider color gamut and greater saturation, but are water soluble (photo 8). Papers designed specifically for dye printers include: HP Premium Photo Paper and Ilford Galerie Classic Gloss. Pigment inks are more light stable, are more insoluble in water, and there is a larger variety of paper choices. Common pigment only papers include Ilford Galerie Smooth and Epson papers. Most dye inks are paired with gloss or satin photographs, while pigment inks are used with coated DFA papers. Then there are the coated DFA and photo papers that will work with either dye or pigment inks including Crescent Digital Papers, and Hahnemuhle Photo Rag.

Photo 8: Water on Microporous RC Paper

Photo 8: Water on Microporous RC Paper

As in photo 7 water drop will evaporate rather than soaking into the coating, but dyes are water soluble and can run or bleed while evaporating. This is also what occurs when using paper designed for pigment ink on a dye based printer. Epson Glossy Photo Paper, microporous for pigment on dye printer.

Aside from straight dye and pigment, there is also a third hybrid category of ink which combine both dye and pigment. Examples of this are Epson's Ultrachrome Ink with a lightfastness expectancy of 100-150 years when printed on designated paper, and Epson Archival Pigmented Ink with a life expectancy of 200 years.

Tolerance Results and Mounting

Though the results of this Epson test on assorted swellable, porous, microporous, and resin coated papers is somewhat inconclusive, all indicators point toward swellable photo papers being heat sensitive at most dry mount temperatures, even as low as F150. Swellable DFA papers, however, mount at all temperatures and even tolerate laminating with no color shift.

The entire pigment ink, paper, heat tolerance test will most likely turn into a full blown article later this year, but for now be aware of mounting limitations with digital photos. Most manufacturers do not list type of paper or coating on their packaging, so if a photo is brought in for framing it is imperative you establish brand, printer and ink. Requesting a blank or discarded image on the same photo paper will easily determine a heat sensitive swellable paper by adding a drop of water.

Understanding

digital papers is the key to protecting yourself when mounting, and the bottom

line remains...if you cannot determine the origin, cold mount or use

preservation techniques to be safe.

END

Copyright © 2006 Chris A Paschke

For more articles on mounting basics look under the mounting section in Articles by Subject.

Additional information on all types of mounting is found in:

The Mounting and Laminating Handbook, Second Edition, 2002,

The Mounting And Laminating Handbook, Third Edition, 2008 and

Creative Mounting, Wrapping, And Laminating, 2000 will teach you everything you need to know about getting the most from your dry mount equipment and materials as an innovative frame designer.

All books are available from Designs Ink Publishing through this website.

Chris A Paschke, CPF GCF

Designs Ink

Designs Ink Publishing

785 Tucker Road, Suite G-183

Tehachapi, CA 93561

P 661-821-2188

chris@designsinkart.com

Photo 1: Epson Heat Tolerance Test

Photo 1: Epson Heat Tolerance Test Photo 2: DFA and Photo Papers

Photo 2: DFA and Photo Papers Photo 3: Swellable Coated vs. Uncoated DFA

Photo 3: Swellable Coated vs. Uncoated DFA Photo 4: Color Variations

Photo 4: Color Variations Photo 5: Water on Swellable Coating

Photo 5: Water on Swellable Coating

Photo 6: Water on Porous Coating

Photo 6: Water on Porous Coating

Photo 7: Water on Porous Resin Coated Paper

Photo 7: Water on Porous Resin Coated Paper Photo 8: Water on Microporous RC Paper

Photo 8: Water on Microporous RC Paper