Photo 1

Photo 1

This latticework mat is an excellent example of using a CMC to its full potential. Not only by design, but profits. Framed artwork courtesy of Eclipse, Kaibab Industries.

When I began this series, little did I realize the true profit potential that lie within a CMC investment. True, I discussed the basic understood benefits of not requiring a full time employee and that of fewer mistakes, but never did I expect to see the potential of design sales skyrocket as you may see in this month's article on pricing.

Asian Latticework

In the first article I showed an Asian multiple opening mat that is a pricing nightmare. Traditional mat cutting may have never thought to design something of this complexity, and even the mere suggestion would put fear in the heart of even the most skilled mat cutting specialist. In fact even the more basic 10 opening mat was feared and often avoided. With today's CMC we can not only cut a 10 opening mat, but we can make it a double or triple without a blink.

Consider the technical aspects of the featured Asian Lattice design. It is a 16x20" double mat, with one hundred thirty-seven (137) openings in the bottom mat alone. There are thirty-four openings in each corner with one central window 4-¾" x 6-½" cut in a black surface paper black core 4 ply board. The top mat has four (4) openings, one at each corner with one central window mat 5-¼" x 7" cut on a Crescent BriteCore with red core. The corner openings are a single central corner offset 6-⅜" x 8-⅜". And if the number of openings is not enough to take your breath away, there are twenty-five ⅜" squares, forty 1" x ⅝" T shapes, seventy-two 1" x 1" plus shapes, for a total of 1284 corners in the bottom mat alone. The top mat has another 28 corners making this a 1312 corner double mat design.

Photo 1

Photo 1

This latticework mat is an excellent example of using a CMC to its full potential. Not only by design, but profits. Framed artwork courtesy of Eclipse, Kaibab Industries.

This is truly a great example of decorative art framing, since the viewers eye actively scans the latticework every bit as much as the small inner Asian maid playing the flute. The red bevel accents of the BriteCore rare also accent and unify the chosen red frame and red silk within the small open edition print.

The Basics

Many people put CMCs through their paces when testing them at shows. They ask to see a star, a name, a keyhole corner then ask where to sign. Only to get the new CMC home and then set it free only on rectangles and ovals. True that even these basics will make money, save time, and create long term happy customers. But there is so much more possible.

Since you are now showing potential decorative corners as samples either on the wall, the monitor, or photo album, they are also creeping into routine designs. But even the most basic offset corner window mat should cost more than it's rectangular sibling. So, how do we price these?

Traditional vs. CMC Pricing

"Pricing is intellectual, not emotional," says Jay Goltz. Pricing must take into account all overhead costs including boards, materials, square footage, design labor, production labor AND profit. Labor charges for matting includes both manual cutting or CMC cutting and front counter designing and sales. CMC cutting is like selling mounting as it helps make the framed presentation look better, prettier, and perhaps more desirable to the customer.

Traditionally there have (and continue to be) suggested price charts available from distributors and industry surveys, but these do not really originate from manufacturers. Pricing should be based on your own numbers, hourly shop time and profit. It seems the world has changed. Manual mat cutting used to be a very labor intensive process whereas now the CMC can be a capital expenditure demanding considerations never before necessary, like recouping cost of the machine.

A new mat cutter (CMC) now falls into the same category as the purchase of a large hot/cold mounting press or underpinner. For the first time a mat cutter is going to cost much more than the thousand dollar investment of a professional level straightline mat cutter, and recouping that capital expenditure is part of the pricing overhead. The cutter must actively work not only to make mat cutting easier, but it must also strive to pay for itself...in other words, to earn its keep.

Square Footage

Never take lightly the fact that a traditional cutter takes up only 2' x 5' of table space but that a CMC will potentially require as much floor space as a 4' x 8' vacuum mounting press. I have taught for years about the mounting potential of a dry mount press, touting maximum profit potential only when it is in operation every minute of every working day. That is because part of the overhead of a press (as well as a CMC) includes the amount of space it takes up just sitting there. A well designed press area for a 4' x 8' press, could require up to 10' x 30', or 300 square feet, when including the table set up, press, and cooling area. At an average annual floor cost of $15 per square foot that press needs to take in $4500 annually to just sit there unused, holding the floor down.

With a traditional mat cutter the allocated floor space is much smaller and at times the cutter can be moved off the cutting table to make additional space for oversized projects. The CMC will require about 10'x 10' or 100 square feet of floor space, and at $15 per square foot annually needs to recoup $1500 per year in its mat cutting price calculations. This is above capital expenditure, cost of matboard, labor, profit and assorted other overhead.

CMC vs. Manual Labor

The number one problem in calculating pricing is that with a CMC is there are no incremental costs. Like the above dry mount press it takes up space and that must be calculated into prices. There are many benefits to having an expeditious, robotic computer cutting mats, but here are tradeoffs too.

What is saved in manual layout and cutting time has been replaced with design time at the front counter. It's not that we do less work, we only do it in a different location. More time is taken creating the layout on the monitor as well as showcasing the options for the customer in general. When there are hundreds, maybe thousands, of combinations and options it takes longer to sort through them. Cut corner samples trigger lots of ideas but the designer combinations remain endless.

No Such Thing as Pure Profit

I have been told by manufacturers promoting CMCs that once the design is programmed then using it again is pure profit. Fairly true in theory, but remember there is still an operator being paid by the hour; still additional design time spent with the new customer; still material costs; still square footage floor space to be paid; still other overhead expenses of electricity, insurance and routine maintenance on the equipment to be paid out prior to profit. Don't be naive about profits. I've heard myself say "...almost pure profit..." when actually it is more of a value added concept, time saver or stress reducer. Profits will be increased but there is always a cost connected.

Time Saved Time Burned

It must be remembered that a CMC is still a mat cutter, and that it requires blade changes and slight adjustments as different boards are selected to cut. All 4-ply boards are not created equal, some are thicker than others, though all still called 4-ply. Will a CMC cut all kinds of boards? Of course, but if it takes additional time to adjust and test, and additional boards to also test cut, then this time and these supplies must be also covered during pricing.

Photo 2

Photo 2

An angled detail of the featured design better shows the double mats are attached then spaced away from the creme backing mat with a ⅛" foam spacer. The 3-D nature of the design and resulting shadows makes it difficult to photograph this without appearing fuzzy.

It matters not whether you have a professional straightline cutter or CMC, maintenance and adjustments must be made either way. And just as with a manual mat cutter, the CMC mat will only be as professional and as perfected as the operator of the machine itself.

Pricing Theories

When questioning manufacturers about their pricing suggestions for this article I received numerous comments. Generally there was no fixed concept or answer. Suggestions were made to look into POS systems for mat pricing, but I fear they have yet to truly fit the concepts of the CMC. Industry information appears sketchy and suggested distributor price lists don't seem to address CMCs as a new pricing concept.

Framers have been chatting about how they are pricing CMCs in their own operation. Seems there has been no real formula or structure to use there either. It seems that CMC pricing has been established by a number of different methods including traditional manual mat cutting pricing; pricing by shop time; pricing by window opening; pricing by the corner; or as will be suggested here, a new method...one to better fit the new technology.

Charging based on hourly shop time by including selling/design time + layout time is an option but often difficult to estimate on elaborate layouts, like the Asian Lattice sample. Charging by number of openings doesn't address the variability of rectangular designs being much simpler to cut than a decorative keyhole corner. The keyhole should obviously price more, but what about a double offset, or cathedral arch? Too many variations are possible, and there are still elements missing, like the cost of the materials used, design time, overhead, and profits.

Charging by the number of corners might be the ticket, or at least going in the right direction. But with this formula at $.50 per corner the featured Asian Lattice double mat with 1312 corner double mat design would sell for over $600. By calculating prices this way the difficulty of a decorative opening will be addressed as well as the additional corner cut charges on a leased machine, but you might not sell many.

Pricing per Goltz

I recently discussed CMC pricing with Jay Goltz, industry pricing expert. We recognized and agreed the traditional mat pricing structures no longer work when applied to CMC use. You can't use old mat pricing, not even by adjusting old mat pricing, but rather we need to establish a new pricing structure. One that better fits the new cutter, new technology, new thinking, new design potential which all equals a new pricing structure altogether. The new CMC machine has to be fed to pay for itself and that only happens by running designs through it. The more unusual, the more involved, the more technological, the more twenty-first century, the more will be sold and the more profits there will be.

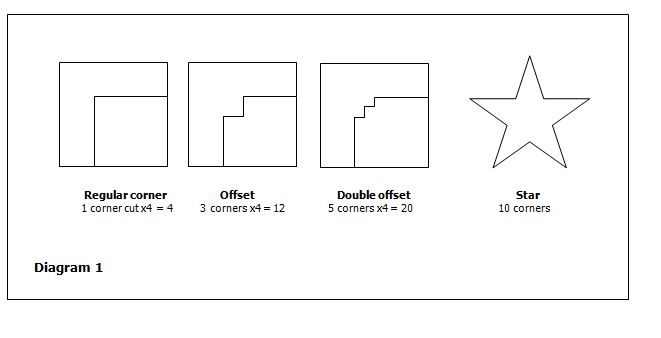

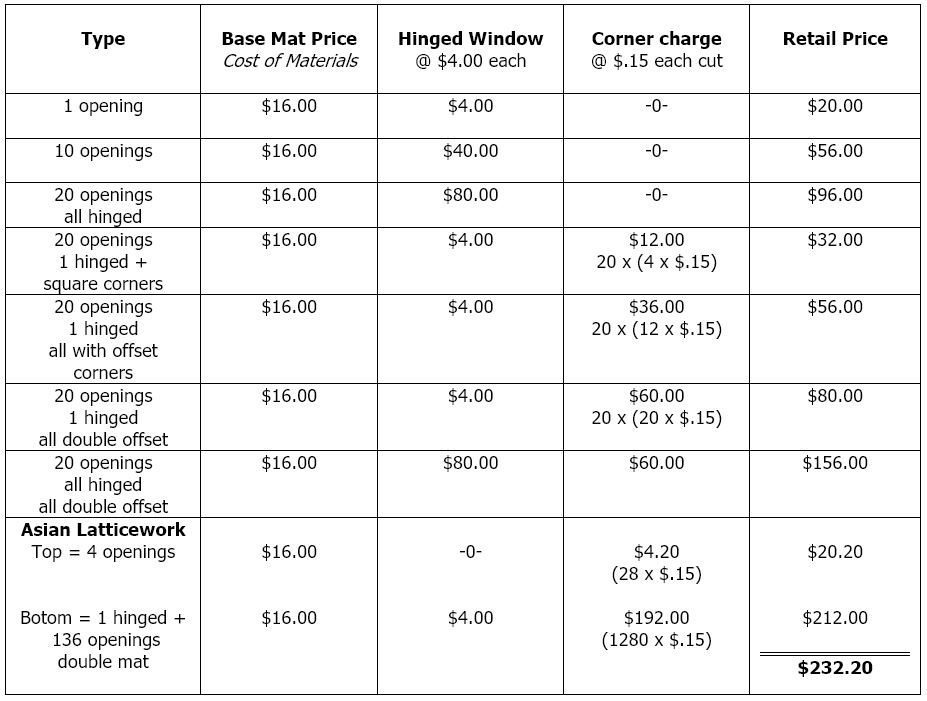

After assorted potential formulations it seems that charging by the corner cut is the best way to begin. If the corner cuts cost the framer $.05 each then at 3x markup the corner cuts should price at least $.15 each. This means per corner turn, not the four basic corners of the window itself. So a single offset corner would have three (3) corner cuts per window corner (4 corners) of the design (3 x 4 = 12 total cuts), a double offset would have five (5) cuts per corner (5 x 4 = 20), and a star opening would have ten total corner cuts (diagram 1).

The Formula

Average shop times vary between $50 - $75 per hour . At $50.00 that's $.80 per minute. If it takes 5 minutes to cut a window opening that's 5 x $.80 = $4 per opening, based on hourly rate. Add to that the materials and that's the basic mat cost. The mat cost should be 3x materials PLUS 3x labor. Cost of good sold means materials plus labor.

If the mat has twenty openings, begin with the base price for the size mat needed and add $4 for every other opening that has hinged art behind it. So the twenty opening mat would sell for the basic mat charge ($16) + 20 x $4 ($80.00) = $96. The same mat with only one hinged window opening would be $16 + 20 times $.60 per 4 corner opening ($12.00) = $38.

Now if that twenty opening 16" x 20" mat has offset corners in each opening the price would be base mat + 20 x $4 + 20 x ( $.15 x12 corner cuts = $1.80 each decorative corner). Or $16 + $80 + $36 = $ 132. A quick review is base mat charge for size needed (included or add $4 per window) and add $.15 per corner cut in the overall design (diagram 2).

Formula to Asian Lattice

The bottom mat is a 16x20" single window mat with 136 decorative openings. Say the base mat is $16, add $4 for the window = $20, multiply 1280 corners x $.15 = $192.00 so the bottom mat would price at $212. The top mat has five decorative openings with 28 corners, or $16, + (28 corners x $.15 = $4.20) pricing it at $20.20. The double mat would be priced than at $212 + $20.20 = $232.20.

Same Design Different Wall

One way to feed the CMC by using the same design is during the initial sale. Suggest a duplicate design job of that very twenty opening mat of the family for the summer home, office, or for Grandma's house. With the immediate turn around of digital duplication available from photo labs, a complete set of images can be reproduced as an additional service to your customer by you from the lab around the corner. You make the call to the lab, do the leg work, then create the duplicate framing job.

Photo 3

Photo 3

This corner detail clearly shows the assortment of decorative openings cut with a CMC. Identify the small squares, T shapes, and plus shapes for better understanding the article.

Service to the customer, no muss, no fuss, and you make another good sale in the process. For services like this add shop time to the sale by subcontracting to the photo lab to do the new images and then charging the customer the lab fees plus your labor for doing the work as a single added fee.

Wizard to the Rescue

Recently I spoke with Edd Pratt from Wizard, International about a Marketing and Pricing Plan they are working on with Jay Goltz. They selected Jay because of his vast experience as a successful businessman who has successfully incorporated CMCs into his operation. This plan is intended for all Wizard customers and will become part of their regular rental and/or sales packages.

This kind of help is long overdue and is slated to have been released by Wizard during the Atlanta show. Probably old news at this printing and I currently have no details, but it sounds like the complete pricing guide we have been looking for. Wizard needs to be applauded for rising to the occasion over this issue.

Final Fitting

No doubt this all sounds rather confusing as pricing usually does. The theory is relatively simple yet calculations will be necessary at the time of each sale. A price chart or listing column in your current pricing programs may need to be implemented. In any event, the point is never to charge less when may cutting with a CMC because of thinking the labor is less. Remember all the costs and charge fairly. Giving away your profits may be a humanitarian thing to do but aren't you in service retail to also earn a decent living?

END

Copyright © 2001 Chris A Paschke

NOTE: Again I'd like to thank Mark at Eclipse, Matt from Fletcher, and Edd Pratt from Wizard for their assistance on the information contained in this article. Also Jay Goltz for our extended brain storming over this pricing issue.

For more articles on mounting basics look under the mounting section in Articles by Subject.

Additional information on all types of mounting is found in:

The Mounting and Laminating Handbook, Second Edition, 2002,

The Mounting And Laminating Handbook, Third Edition, 2008 and

Creative Mounting, Wrapping, And Laminating, 2000 will teach you everything you need to know about getting the most from your dry mount equipment and materials as an innovative frame designer.

All books are available from Designs Ink Publishing through this website.

Chris A Paschke, CPF GCF

Designs Ink

Designs Ink Publishing

785 Tucker Road, Suite G-183

Tehachapi, CA 93561

P 661-821-2188

chris@designsinkart.com