Photo 1

Photo 1

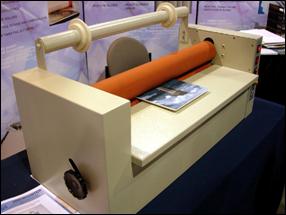

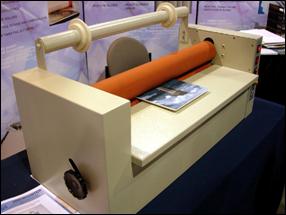

The M65 Mini Mounter from Remington Laminations, Grand Prairie TX is a 27" tabletop motorized machine designed for pre-coating substrates with adhesive or surface coating, but has a limited clearance of ⅜".

Current trends in digital graphics, wide format inkjet XE "inkjet" in advertising, and exterior fine art is rapidly expanding the marketing potential for custom framers beyond just wall décor. Many businesses are already offering on-site image repair, modification and enlargements as fine art options, and with heat-sensitive digital images being framed, rollers are now a logical addition—more than a mere option—to most custom framing equipment. That said, what decisions surround the purchase of an RL?

Selecting a Roller Laminator

The options are numerous: manual or automatic; production mounting or one at a time; limited thickness settings or variable thickness adjustment; cold rollers for pressure-sensitive films or hot settings for heat activated films. Whether a 44" cold or 80" hot/cold laminator is desired, there are many decisions to be made prior to final selection and purchase. Three basic consideration are—know your competition, review marketing potential, and create a five year plan.

One must research who else offers large scale—or any—RL services in town, and what types of images are they capable of bonding. Once purchasing an RL, both mounting and laminating procedures are required to grow your business. RL mounting is the permanent bonding of an image to a rigid substrate, laminating applies surface films for durability, and encapsulation—two sided permanent lamination—coats both sides with film, like an ID card. Be ready to take them all on.

Are you considering in-house wide format printing within the next five years? How large? Are these images commercial or fine art? And finally—what is the impact to future expansion if a smaller machine is purchased?

Types of RLs

If your five year plan does not include commercial applications of exterior signage and only a few images cold mounted weekly, a small hands-on AMS Manual Press might be just fine. Routine daily mountings would indicate the need for a larger entry level cold RL. Look for features of easy load, safety, reset, speed, and pressure controls. Also consider routine maintenance costs and service after the sale.

Cold RLs, roll laminators, and roller machines are available from a number of manufacturers as both manual and automated models, that can mount boards up to 2" thick. A variety of adhesives and laminates are available as rolls and high tack acrylic PSAs (pressure-sensitive adhesives). Their highly aggressive nature precludes using RL adhesives in a cold vacuum frame because of alignment difficulty and their lack of repositionability. If all air is not compressed from between all layers during initial application a vacuum frame will leave trapped air bubbles. Complete confidence and knowledge in mounting methods must be achieved prior to execution. These adhesives are permanent and not very forgiving. Popular cold machines include AMS Quick Mount, Remington M65 (photo 1), and Drytac JetMounters (photo 2).

Photo 1

Photo 1

The M65 Mini Mounter from Remington Laminations, Grand Prairie TX is a 27" tabletop motorized machine designed for pre-coating substrates with adhesive or surface coating, but has a limited clearance of ⅜".

Photo 2

Photo 2

Drytac JM26 Jet Mounter cold-mount laminator has feed roll adjustable width up to ¾" and power feed.

Thermal RLs have been used for decades in the sign and photo markets, but hot RLs are less likely to fit a framer's needs. The AMS 42 Pro, Neschen Seal Ultra series, and D&K machines might be logical choices if heat is desired. Hot/cold RLs will mount and laminate all temps, all types of materials, but their limitations need to be reviewed before purchase. Cold RLs are a more economical investment than heated machines, but the films are higher in price. Cold machines cannot encapsulate for exterior use, while hot rollers cannot face mount. And pouch or roller press units (below) though economical often use only specialized materials.

Roller Presses

Pouch laminators, roller machines and roller press variations are small closed machines made by a number of companies as an affordable, fast, efficient alternative to an RL. They have substrate adjustment settings, preset heat control, forward and reverse, adjustable speeds, in some cases hot or cold operation, are low maintenance, and will encapsulate sensitive inkjet and other digitals. Manual cold laminators will safely mount P-S films and boards.

Photo 3

Photo 3

Bienfang Roller Press bonds P-S or heat activated materials, on a limited number of pre-selected settings.

The Bienfang Roller Press (photo 3), Neschen ProSeal 25 and 44 (photo 4), AMS 42 (photo 5) and other closed units are modified RLs that have mounting and laminating capabilities. Roller temperatures are high, but the boards feed through fast enough to consider them a low temperature laminating machine. It is the time/temp ratio and duration of actual contact that establishes material tolerances. Having been developed for the framing market they are table top machines under 45" wide, that mount most dry tissues, HA boards, and special pouch boards.

Photo 4

Photo 4

Neschen ProSEAL is available in 25 and 44" models for easy one-step mounting and laminating.

The limitations for closed machines are they do not allow for wrapping and laminating creativity as available with mechanical dry mount or hot vacuum presses. And they may limit the use of traditional roll laminating films used in the creative applications by allowing only special low temperature films to be used.

Photo 5

Photo 5

AMS 42 RL heated tabletop closed unit has adjustable roller temp, pressure, and reversible settings.

Maintenance and Materials

Clean work areas are imperative when using RLs. Absolute dust free environments are impossible to achieve if machines are placed near saws, or mat cutters. The release liner creates added static electrical charges that will attract particles, which may not be removed after trapped between layers. Exposed adhesive on feed rollers must be discarded prior to beginning the first project each day.

Commercial P-S boards are perfect for the occasional cold mounting of a heat sensitive image in a manual, cold roller laminator or closed unit system. Select a high tack board or film for most long term aggressive bond (photo 6).

Photo 6

Photo 6

(L-R) Bienfang, Crescent PerfectMount, Bainbridge, Alcan, Gilman, and Drytac High Tack (unmarked liners).

The two things that make cold RLs the most valuable to framers is their potential for face mounting of images to the back side of PMMA (acrylic sheeting), and photos to the surface of nonporous aluminum composite using a high tack P-S film such as Neschen Gudy 870 (photo 7). Alcan Dibond is available in 4'x8' sheets brushed silver, brushed gold, as well as white and assorted colors.

Photo 7

Photo 7

Photos were flat mounted with a cold JM26 using high tack Neschen Gudy 870 to Dibond aluminum composite.

Final Roll

A roller laminator of one kind or another will undoubtedly make its way into most successful contemporary frame shops. Regardless of the machine of choice they will allow the full service framer to mount lengthy 27x92" wrap around photos as well as suspect heat sensitive digitals. Not a bad idea.*

END

Copyright © 2009 Chris A Paschke

For more articles on mounting basics look under the mounting section in Articles by Subject.

Additional information on all types of mounting is found in:

The Mounting and Laminating Handbook, Second Edition, 2002,

The Mounting And Laminating Handbook, Third Edition, 2008 and

Creative Mounting, Wrapping, And Laminating, 2000 will teach you everything you need to know about getting the most from your dry mount equipment and materials as an innovative frame designer.

All books are available from Designs Ink Publishing through this website.

Chris A Paschke, CPF GCF

Designs Ink

Designs Ink Publishing

785 Tucker Road, Suite G-183

Tehachapi, CA 93561

P 661-821-2188

chris@designsinkart.com