Photo 1

Photo 1

Professional famers are a cut above the do-it-yourself artist or crafter in their knowledge of framing materials and should always promote the best and safest way to enclose and exhibit any customer art. Small alterations in hardware or wire selection can significantly increase the stability and safety of custom framing, remembering the hanging system is only as dependable as its weakest link.

Screws

The weight or gauge of a screw is based on shaft dimensions and threading. To simplify identification of smaller, more commonly used screws a number designation preceded by the # sign has been adopted with #0 the smallest and #15 the largest. In framing #4 or #6 are most common, with #3 and #8 occasionally needed.

Screws are identified by shaft # (#4, #6, #8); category (Wood, Metal); head style (Flat head/Countersink, Pan head, Round head); and drive (Slotted, Phillips, Combination, Pozi-UK). Wood screws have a coarser pitch (few threads per inch) than sheet metal or machine screws, and often have an unthreaded shank below the head. The threadless shank allows the top piece of wood to be pulled flush against the under piece without getting caught on the threads. They are available with countersink or pan heads. Metal screws have sharp threads that cut into a material such as sheet metal, plastic or wood. They make excellent fasteners for attaching metal hardware to wood because the fully threaded shaft provides good retention in wood (photo 1).

Photo 1

Photo 1

Flat head screws are chosen for countersinking when the head needs to be flush with the wood surface. Round head screws have a domed shape, while pan head screws have a slightly rounded head with short vertical sides. Pan head or round head are most common for D-rings, D-straps and steel plate hangers. There are many drive configurations but straight slotted, Phillips, combination and Pozi are most common for framing.

Sawtooth hangers

The typical sawtooth hanger is a jagged edged metal strip 1-2" long that resembles a saw edge (photo 2). Unfortunately sawtooth hangers get quite a bad rap because of hanging failure, though it is not the weakness of the metal strip but rather the softness of the moulding that is the weakness. Most sawtooth hardware comes with short ⅜" to ½" tacks (pins) or are all-in-one "nailess" sawtooth hangers for attaching it to a painted panel or frame. If the wood is soft, pressed tacks can pull out of the frame due to weight and gravity. A simple solution to prevent failure is to replace the tack with a small #3 x ¼" metal screw to insure they will not pull out.

Photo 2

Photo 2

There are also adjustable sawtooth called CWH Hangers from LION Picture Frame Supplies, which allows art to lie flush against the wall when hung (photo 3). They are modestly adjustable after installation and mount to wood, polymer or aluminum frame to support up to 32 pounds. Hangers are individually designed for canvas art on stretchers, frames with hollow back, frames with flat or papered backs, and aluminum frames with a channel.

Photo 3

Photo 3

Screweyes

A screw with a looped head is called an eye screw, eye hook, screw eye or screweye, which are designed as an attachment point for wire. When installing screweyes into hardwood such as maple, oak or walnut, stresses occur at the transition point where the screw meets the eye which weakens it. If too small an eye has been selected for too hard a wood the eye can twist off from the inserted screw. In soft or reconstituted wood such as MDF the threading can create sawdust rather than grabbing the wood grain as it is inserted which allows for the screw to pull out (photo 4). Also insertion of a large eye forces the frame away from the wall; can leave a mark on the wall; or split the sides of narrow moulding.

Photo 4

Photo 4

D-Rings and Strap Hangers

D-rings come in zinc, nickel, brass and bronze as small 1-hole or 2-hole styles (photo 5). Heavy duty three-hole strap hangers are constructed of heavier steel, accommodate #6 x ½" screws and may be hung with or without wire for wood frames, mirrors, gallery wraps or cradled boxes. If hung without wire they are aligned vertically at the upper corners on the back of the frame and suspended directly on substantial picture hooks or screws anchored into the wall. There are many styles not featured here but allow for huge variety and the possibility to easily match the hanger with the specific frame.

Photo 5

Photo 5

Steel Anchor Plates

Anchor plates are an alternative to strap hangers and are sold as 2-hole and 4-hole styles with screw holes located both above and below the ring for attaching the wire (photo 6). They are designed to be mounted vertically ¼ to ⅓ down from the top edge of the frame, either centered on a narrow moulding or about ½" from the inner edge of a wider moulding, and may be used with #4 or #6 pan or Pozi screws in varying lengths appropriate for the moulding. The 4-Hole Super Steel Hanger is 3-½" long, ¼" wide for heavy art and supports up to 100 lbs. The shorter 2-Hole Super Steel Hanger is 2" long, ¼" wide for art up to 50 lbs. The longer 4-hole version has staggered holes to dissipate the stress of the wood, reduces hardwood splitting, plus multiple screws increases screw security with MDF or soft wood.

Photo 6

Photo 6

Flanger Hangers

When a frame is too narrow for a D-ring, strap or steel hanger, another option is the Flanger. It has a 90 degree bend along its full length to grip the inside edge of a narrow frame moulding reducing the risk of wood splitting by eliminating twisting or screw tear-out (photo 7). It minimizes bowing, gives the frame more strength and stability, and its flat profile holds closer to the wall. Wire attachment is slightly angled so hardware is sold as mirror-image pairs marked L for R. Flanger Narrow Hanger fits ¼" to ½" mouldings and supports up to 50 lbs. Flanger Medium Hanger fits ½" to 1" mouldings and supports up to 70 lbs, Flanger Wide Hanger fits mouldings 1-4" and will support 100 lbs.

Photo 7

Photo 7

Wire

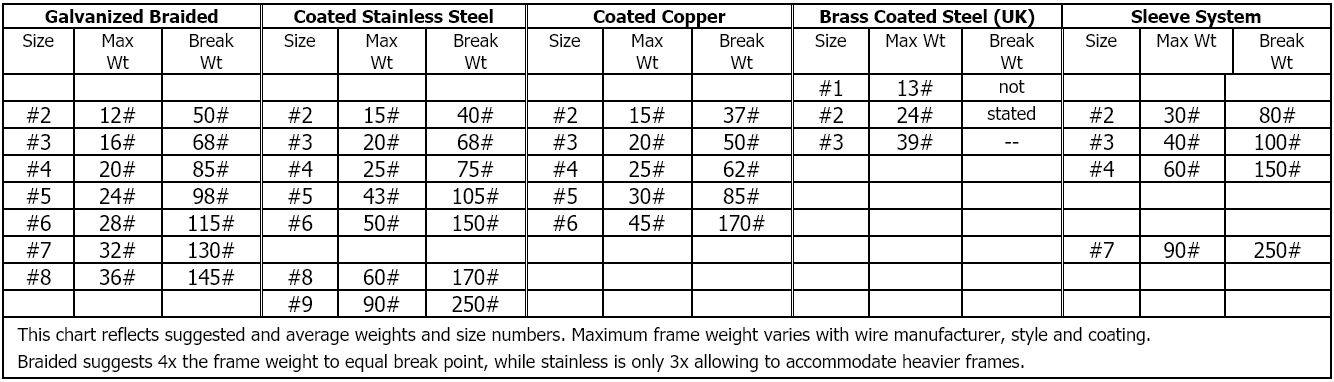

Selecting the correct wire to support your framed is every bit as important as using the right hardware. Picture frame wire comes in many different types and weights (photo 8). There is multi-strand braided galvanized steel, twisted stainless steel, stainless plastic coated, copper plastic coated, brass coated steel (UK) and nylon coated sleeve systems. Galvanized is most popular with artists, but least effective. Plastic coated stainless will not mar walls, hurt hands during installation, rust or discolor. Coated copper is softer and easier to work with but does not have the strength of stainless steel. Brass coated surrounds a single rust-resistant steel strand, but the coating can crack which compromises the strength of the wire.

Photo 8

Photo 8

As braided galvanized steel wire diameter increases the strands remain constant in size but additional strands are added to the braid. A #2 braided wire has 12 strands while a #8 braided has 36 strands. In contrast, all stainless steel wire contains seven strands that have been tension twisted like a cable, and as the wire gets larger the strands increase in diameter. This makes twisted wires comparatively stronger than braided, but also less flexible.

Choosing the correct weight wire will vary depending upon the type of wire selected. The break strength of a braided wire should be four times the weight of the frame, while the break strength of a coated stainlessis three times the frame. A 10 pound painting requires a 30 pound maximum weight stainless wire, but a 40 pound braided wire. A #3 braided wire has a maximum capacity of 16 pounds while a #3 stainless steel picture wire has a maximum strength of 20 pounds. Though a #3 braided and #3 stainless have the same break point at 68# the cabled stainless wire can handle a heavier painting. The larger/heavier the wire the more the variance between braided and cabled structure. A #8 braided is rated at 36 pounds with a 145# break point, while #8 stainless is 60 pounds with 170# break point. Note the softer coated copper has a break strength of 170 pounds, but a maximum frame weight of only 40 pounds.

Sleeve (ferrule) systems offer a very high end appearance and are easy to install, but run more than coated wire. Sevalon, Eagle Klaw and Surflon are nylon coated crimper systems for wiring frames. The coated stainless is available in black, bronze and clear coating with matching crimp sleeves (photo 9). A crimping tool is necessary to crush the metal sleeve that holds clamps the wire in place. The wire should be fed through the sleeve, around the hanger of choice then slid back through the sleeve. To assure it will not slip the wire may be turned back and passed through the ferrule a third time. Make certain the sleeve is well crimped.

Photo 9

Photo 9

When choosing wire pay attention to the types and weights of frames you will be hanging. Most likely a coated stainless steel wire will be your best choice, and probably a #3 and #5 will handle most all your demands. Keep in mind it is better to select a wire too heavy than too light.

END

Copyright © 2014 Chris A Paschke

Note: Much of the hardware discussed in this article is used in the USA as well as UK, but LION carries a huge variety of hangers and plates far more versatile than the few mentioned under D-rings and hangers that are not available in the USA.

For more articles on mounting basics look under the mounting section in Articles by Subject.

Additional information on all types of mounting is found in:

The Mounting and Laminating Handbook, Second Edition, 2002,

The Mounting And Laminating Handbook, Third Edition, 2008 and

Creative Mounting, Wrapping, And Laminating, 2000 will teach you everything you need to know about getting the most from your dry mount equipment and materials as an innovative frame designer.

All books are available from Designs Ink Publishing through this website.

Chris A Paschke, CPF GCF

Designs Ink

Designs Ink Publishing

785 Tucker Road, Suite G-183

Tehachapi, CA 93561

P 661-821-2188

chris@designsinkart.com