Photo 1

Photo 1

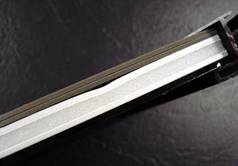

Standard issue U-shaped spring clips made of spring steel.

We all know what spring clips are, the U-shaped metal band made of spring steel used to retain artwork in sectional metal frames that are often sold as part of a basic hardware package (photo 1). Framers also know they are designed for filling the extra space between the mat package and the back of the metal frame lip (photo 2). They are easy to install, reusable, and fill a range of voids. They are used as a routinely as brown Kraft paper for everyday framing but they are not a preservation item. True they are steel and therefore neutral pH and acid free, but their very action is what makes them not favorable for preservation applications.

Photo 1

Photo 1

Standard issue U-shaped spring clips made of spring steel.

Photo 2

Photo 2

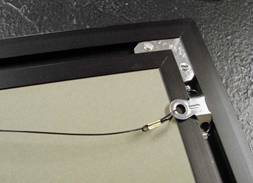

Spring clip applies pressure between back lip of frame and mat or painted panel.

The very pressure that holds the backing boards and glass against the front lip of the frame is same thing that creates unfavorable pressure points along the perimeters of the art. The narrower the fill space the tighter the spring clip and the greater the pressure that is produced. The strength of a clip can easily indent foam center board at the pressure points around the frame perimeter as seen in photo 3. Foam center board easily absorbs the compression damage of the indentations somewhat equalizing potential damage to the mat. But if the backing board is a paper base 4-ply product rather than foam it cannot absorb that pressure and potential damage translates directly to the window mat. In humid environments—a typical bathroom or geographic location such as Houston TX—paper fibers are subjected to expansion due to moisture saturation. Consider a mat that absorbs moisture and is allowed to naturally expand between the spring slips but nut under them, uneven warping can occur. Once paper fibers have swelled with moisture they will never retract to their original size, even once thoroughly dry. If severe enough, this warping will be visible from the front of the frame.

Photo 3

Photo 3

The small indent shows the pressure point that compressed the foam board.

Photo 4

Photo 4

(front to back) Glass, mat package and open fill space. Two 4-ply mat blanks fit the space as filler

The best way to avoid pressure point damage is to eliminate the pressure points by cutting same size filler boards from scuffed or surface damaged, unusable mat blanks or foam center board. Once spring clips are removed from a frame the fit space is evident when pressing the package to the front of the frame (photo 4). The fit space in the sample frame allows for two faded 4-ply mat blanks to be cut to size and slipped into the metal frame channel (photo 5). Once bolted together the package is fully filled and fitted and ready to hang with no potential of pressure point damage (photo 6).

Photo 5

Photo 5

Two piece of faded 4-ply are cut to fit channel.

Photo 6

Photo 6

Finished, wired frame ready to hang

There are times spring clips might work without any fear of damaging the art, as when installing a stretched canvas into a metal frame (photo 7). That said, canvases aren't frequently placed in metal frames, and one should always consider alternatives such as offset clips. If spring clips are too loose that can snap out and cause injury, as has happened to me in my early years as a framer. So framer beware and consider all the options when selecting hardware.

Photo 7

Photo 7

Spring clip with stretched canvas.

END

Copyright © 2012 Chris A Paschke

For more articles on mounting basics look under the mounting section in Articles by Subject.

Additional information on all types of mounting is found in:

The Mounting and Laminating Handbook, Second Edition, 2002,

The Mounting And Laminating Handbook, Third Edition, 2008 and

Creative Mounting, Wrapping, And Laminating, 2000 will teach you everything you need to know about getting the most from your dry mount equipment and materials as an innovative frame designer.

All books are available from Designs Ink Publishing through this website.

Chris A Paschke, CPF GCF

Designs Ink

Designs Ink Publishing

785 Tucker Road, Suite G-183

Tehachapi, CA 93561

P 661-821-2188

chris@designsinkart.com