Photo 1

Photo 1

Clear polyester film carrier is sandwiched between two layers of acrylic adhesive protected on each side by a clear polyester release liner, best applied with a cold RL.

Mounting photographic and digital images in a contemporary manner that will stand the test of time is one of the challenges for contemporary photographers, galleries and museums. The two forms of face mounting to clear polymethyl methacrylate (PMMA)—acrylic—include a silicone-based gel known as Diasecand PSA film. The papers used, printing process and the display environment are all considered when deciding which form of face mount is best suited for the photograph or print. Digital prints originated in the 1950s but it is since 1990 that new technologies have ensured greater access to wide-format printers and digital cameras with the ability to produce images that can be printed on them.

A Swiss chemist Heinz Sovilla-Brulhart lodged patents in several countries in 1972 for his method of face mounting using a primer and moisture curing silicone rubber to adhere photographic papers to the back of a sheet of clear acrylic. He launched a company, Diasec Sovilla SA, to oversee the production of the primer required in the process, and registered a trademarked name Diasecfor the process. The Diasec mounting method came to the attention of fine art photographers who learned that the mounted images showed good signs of longevity and no color shift. The limited availability of Diasec outside Europe stimulated manufacturers to develop PSAs that attempted to achieve the same bonding and presentation as the Diasec process.

Optically Clear Adhesives

PSA for face and back mounting transparencies is an optically clear acrylic film for bonding to clear substrates like PetG™, Plexiglas™, acrylic, and polycarbonate. Major brands include DaVinci Technologies PermaTrans® IP2100, Drytac Facemount®, D&K Optically Clear Permanent, Seal OptiMount® Ultra, Neschen gudy® ultra clear, LION SeaLion Optically Clear Mounting Film. The film is a clear polyester carrier sandwiched between two layers of acrylic adhesive protected on each side by a clear polyester release liner. It is best applied with an automatic roller cold laminating machine.

Some films are better suited to commercial and short term presentations while others are designed for extended-term indoor applications. Some PMMA sheets can outgas when exposed to high temperatures, creating bubbles and tunnels between the sheets and the mounting film. A major problem associated with the creation of a face mounted image is the tendency for static build-up on the acrylic, which attracts dust particles during the critical mounting period, making it difficult to mount an image without a blister of dust appearing trapped between the surface of the image and the acrylic.

Photo 1

Photo 1

Clear polyester film carrier is sandwiched between two layers of acrylic adhesive protected on each side by a clear polyester release liner, best applied with a cold RL.

D&K Optically Clear Permanent adhesives feature a clear polyester carrier, permanent solvent acrylic adhesive with UV inhibitors to reduce color shift (fading). (photo 1) Neschen manufactures gudy ultra clear and states that the product will provide excellent optical characteristics for up to six years indoors. Drytac Europe Ltd manufactures Facemount optically clear polyester mounting film coated on both sides with solvent acrylic adhesive. A material more suited to fine art images is Facemount UV, optically clear PSA. OptiMount Ultra is manufactured by SEAL—now part of the Neschen Group. OptiMount Ultra is optically clear, double-sided permanent solvent base acrylic adhesive with a polyester carrier.

Face Mount Papers

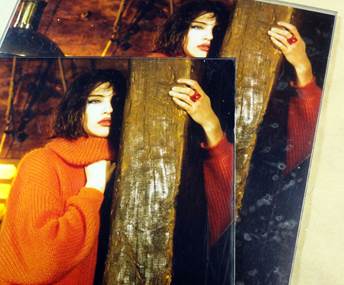

The type of paper used in the printing process will help determine the best method of face-mounting. Diasec was invented for use with photographic papers and contemporary photographic media, including Cibachrome, Duratrans, FujiFlex and Endura Metallic papers. (photo 2)

Photo 2

Photo 2

Duratrans film is a good candidate for facemount. Though optically clear films may be applied manually, it is impossible to achieve a clean result.

Inkjet papers are frequently face mounted with both Diasec and PSA films. Diasec mounting requires a matte inkjet or photo rag paper to enable the adhesive gel to bond with the paper. Inkjet papers with a luster, satin or gloss surface are best with PSA films.

Mounting Steps (in a nutshell, perhaps as a sidebar)

Photos 3-5 are shown courtesy of LION Picture Frame Supplies, UK.

Photo 3

Photo 3

Pass the print through the RL in one smooth motion removing the release liner film as it advances through the rollers. Film will be mounted to the surface of the print with the release film still on the top surface.

Photo 4

Photo 4

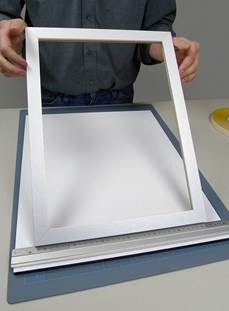

Remove the release film from the front of the acrylic and check carefully. Once checked be very careful not to damage the surface so reapplying the protective sheet is suggested.

Not all prints have backing material, sometimes double-sided adhesive is applied to the back of the mounted image and Sintraor aluminum composite material (ACM) is applied as a protection backing. The recommended method for hanging is the use of a four-sided aluminum or wood sub-frame (lifter) which enhances the rigidity of the work, provides a hanging mechanism for wire, and enables the images to float on the wall. (photo 5) The protection release liner on the front is the last to be removed.

Photo 5

Photo 5

Apply a lifter sub-frame behind the acrylic using high tack, high density (HD) ATG tape. Lifter may be metal or wood frame. Apply hangers to sub-frame.

Pros and Cons

Diasec mounted images processed in the early 1970s still exist, showing negligible color shift, the whites are still pure and there is no evidence of visible acid erosion. Other attributes of face mounting include: colors appear more rich and saturated and the images are considered crystal clear since there is no air space between image and glazing that result in multiple light-reflecting surfaces; since oxygen has a destabilizing effect on organic molecules, the absence of air is chemically beneficial to both traditional gelatin emulsions and the pigments and dyes in digital printing; and images are prevented from distorting, tearing, or suffering from casual accidents that would ordinarily mar the surface.

There are no reliably researched answers surrounding long-term aging of face mounted photos but there are a few potential issues. If the surface acrylic becomes scratched or clouded it may never be removed, making surface damage a permanent part of the art, though anti scratch acrylic products have surface coatings that may prevent this type of damage. Also the adhesive bond may be lost over time resulting in patches of delaminated image, usually close to the edges. As the acrylic sheet expands and contracts with changes in environmental humidity and temperature. The polyester adhesive needs to be flexible enough to move with the acrylic, sometimes losing its flexibility creating a spider web pattern to appear on the surface of the image caused by the creasing of the adhesive film. Some manufacturers claim their adhesives will only last five years indoors, and some early PSA films may yellow over time.

Final Mount

The face mount process is not for the faint-of-heart. A thorough knowledge of print media, technical RL skill, a suitable clean environment, and proper training are required to achieve a high quality end product. Face mounting is not a process for every framer to complete in-house, but should be a technique they understand and they should have a reliable subcontractor for creating what their customer desires. Never send a potential customer away…simply know how to solve their problem.

END

Copyright © 2017 Chris A Paschke

Resources—Items

http://dkgroup.com—Optically Clear Permanent (UV)

http://drytac.com—Facemount®

http://neschen.com—gudy® Ultra Clear

http://sealgraphics.com—OptiMount® Ultra

https://davinci-technologies.com—PermaTrans® PT2100

https://lionpic.co.uk—SeaLion OCMF

For more articles on mounting basics look under the mounting section in Articles by Subject.

Additional information on all types of mounting is found in:

The Mounting and Laminating Handbook, Second Edition, 2002,

The Mounting And Laminating Handbook, Third Edition, 2008 and

Creative Mounting, Wrapping, And Laminating, 2000 will teach you everything you need to know about getting the most from your dry mount equipment and materials as an innovative frame designer.

All books are available from Designs Ink Publishing through this website.

Chris A Paschke, CPF GCF

Designs Ink

Designs Ink Publishing

785 Tucker Road, Suite G-183

Tehachapi, CA 93561

P 661-821-2188

chris@designsinkart.com