Photo 1

Photo 1

Archival mounting is a preservation treatment that is totally reversible if removed from the housing. Artists often request archival mounting for their original art, but don't understand that fusing an original to a backing is often not an option for a framer. What they really desire is for their art to be well bonded to an acid free backing for 100 year long term bonding, that is reversible and non-invasive, which can be a difficult and ethical decision for a framer.

We have been taught never to mount original art, but there are times we bend those rules. Mixed media art is very popular with numerous synthetic materials used in these original creations. In Synthetic Materials-Part 1 assorted synthetic papers, fiber synthetic paper, and stone paper were identified and discussed. In Part 2 we'll look at temperature tolerances, present warnings, and make suggestions for display presentations, never forgetting that textile art is original and unique, generally requiring preservation treatment.

Heat Sensitivity

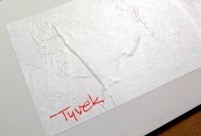

The practice of heat distressing fiber synthetics for tactile and visual texture is common in mixed media as these materials are often dyed, painted, stained and heat cockled as part of the art presentation. In photo 1 notice the visual difference between the lacey visual effect Lutradur polyester delivers when melted vs. the smoother, bubbled effect of melted Tyvek polyethylene. Though the melt temperatures are higher than most mounting adhesives, synthetic sensitivities should be noted and may occur at lower temperatures.

Photo 1

Photo 1

Synthetic materials have variable heat tolerances. The highest melting point is Evolon and TerraSlate that come in at 446°F, but thinner synthetics melt at much lower temperatures between 275°F and 320°F, still much higher than dry mount temperatures. Yupo melts at a 320°F but could pose a problem if other synthetic fabrics with lower melt points were included in a mixed media piece like both Smooth Texture or Soft Texture Tyvek, or TerraSkin. A household iron set on wool runs 300°F shriveling the TerraSkin sample from the high heat. (photo 2) The same sample was tested with a non-rheostat tacking iron and it was fine since the temperature was lower. All synthetics should be tested at the edge or with a scrap from the artist prior to mounting.

Photo 2

Photo 2

I've created a Synthetic Reference Chart for helping to identify the registered manufacturer name of the product, material of origin, general melt point, suggested mounting options or tolerances, and possible techniques and uses. (photo 3/chart 1) The chart obviously cannot cover every synthetic material that shall be encountered in the decades ahead, but the materials may be similar, so keep this for reference.

Photo 3

Photo 3

Dry Mounting

Since Yupo cannot be used with laser printers many people consider it to be heat sensitive, but those are two separate issues. Sheet polypropylene has a temperature tolerance of >275°F with a melt point of 338°F. In a laser printer, paper passes through rollers in the fuser assembly which heats to 390°F in order to bond plastic toner to paper. A dry mount press is far below that temperature, so the question is not press temperature but internal temperatures used by laser printers, and the question is which HA or P-S adhesive will actually bond to synthetic paper. Past testing has verified that 100% polyester encapsulated charts heat bond well on many HA products while polyethylene, polypropylene, and nylon may not.

Heat Activated (HA) boards <150°F would be a fine temperature, but might not meet tear strength criteria for bond strength after fusion. And perhaps a selected adhesive may be ill-advised for use with original fine art. If mounting for matting and glazing, HA boards may bond, but ask your artist for a synthetic scrap to test first. Also if you opt to mount their original, a signed release allowing you to do so should be kept with their records.

Yupo falls into the above category since it generally remains smooth and flat even after painting completion, but fiber synthetic papers like Evolon, Lutradur and Zeelon may not. Since TerraSlate has a low end heat tolerance around 280°F it would probably not tolerate dry mounting, but since it is most often used for signage, menus, or labels it's not likely to require framing mounting treatment.

Test Results

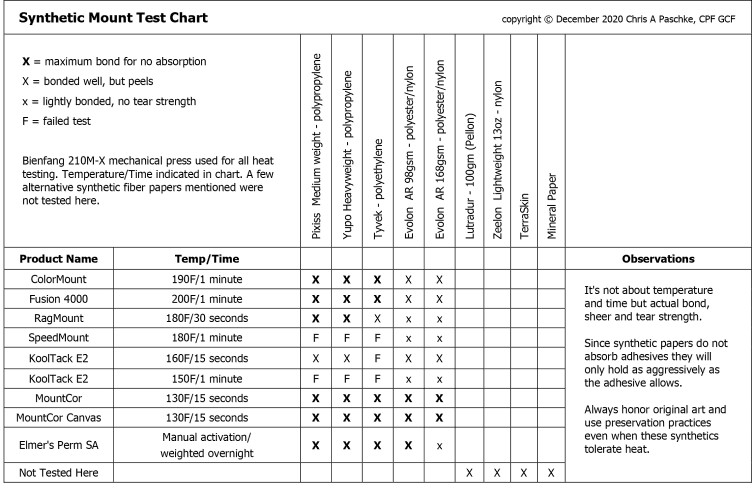

In heat bonding tests completed for this study a cross-section of common rolled adhesives, HA boards and SA boards were tested for tear strength and bond. (photo 4) See Synthetic Mount Chart for results. (photo 5/chart 2) It's not about temperature and time but actual bond, sheer (vertical pull) and tear strength. Since synthetic papers do not absorb adhesives they will only hold as aggressively as the adhesive allows. Always honor original art and use preservation practices even when these synthetics tolerate heat.

Photo 4

Photo 4

Photo 5

Photo 5

P-S Mounting

Mounting with pressure-sensitive adhesive (PSA) is very common for Yupo art, with Sintra® often pressure mounted to a cradled box with the Yupo original mounted to that Sintra. (photo 6) Neschen gudy® 802 is a transparent, two-sided, high tack, permanent, water based, polyacrylate (polyester) PSA film for mounting photos or digital graphics to smooth PVC, Gator, polystyrene, polycarbonate, and aluminum substrates. Gudy 831 uses a long-fiber non-woven paper carrier coated on both sides with high tack, water based, acrylic adhesive, is acid and solvent-free, and has passed the Photographic Activity Test (ISO-18916). Though it is aggressive for bonding synthetic materials with an RL (roller laminator), when manually applied, gudy 831 did not meet tear strength requirements. KoolTack InstaMount is a commercial pressure-sensitive board that has tested well with both Tyvek and Yupo, but has not been tested with TerraSkin or Evolon, which both have a more textual fabric feel.

Photo 6

Photo 6

Though pressure-sensitive adhesives may be manually applied it is not the best application technique, because even when properly applied and weighted bond failure can occur. (photo 7) For efficient, even pressure, use of a cold roller laminator (RL) with aggressive, high-tack PSA adhesive—which does not allow for repositioning—is best when done in a clean room to control dust and dirt. With an RL are two steps to a successful mount—adhesive to substrate, then art to adhesive—and the larger the mount the more difficult the application.

Photo 7

Photo 7

Gel (Wet) Mounting

The internet is full of artist solutions for mounting completed originals to a rigid backing, which perpetuates the thought in the artist community that it is acceptable to mount a completed original. Liquid acrylic mediums, gels and PVA are routinely advocated as a viable wet adhesive by mixed media artists for bonding porous materials, but synthetics do not absorb. Liquid medium is very lightweight and having no viscosity, soaks into a porous board leaving little bonding capability for non-absorbent synthetic paper. Bottom line, bond failure is possible.

Golden Extra Heavy Gel Medium is a thick paste that will bond Yupo to an absorbent rigid substrate, but the end results may not have desired tear strength. Golden Artist Colors do not endorse the use of their gel products with Yupo, and use of it must be considered experimental by nature. This is not a technique to be used with synthetic materials.

Bond Failure

It is the incompatibility of materials that allows for bond failure when working with synthetics. The above mentioned gel is a fabulous adhesive for the fusion of porous materials. The gel will bond to the porous substrate—hardboard, panel or box—but cannot aggressively hold to the Yupo allowing it to be pulled from the substrate. The adhesive remains well fused to the board, it’s the Yupo bond that lets go. Since Yupo cannot absorb, any guarantee of long term fusion is simply not possible.

The same is true for pressure-sensitive adhesive (PSA). Only select high tack films or self-adhesive products will effectively bond layers for dependable long term fusion. In an attempt to achieve surface smoothness Yupo artists are requesting Gatorboard, Dibond or Sintra as a substrate. Like Yupo, Dibond and Sintra do not absorb so only high tack PSA is an option for bonding. Coda Cold-Mount, KoolTack InstaMount, and Neschen gudy all tested well with non-absorbent synthetic materials.

Keep Informed

This article by no means discusses all of the new technology synthetic materials that shall be encountered by a custom framer, but gives a good idea of what to look for and what might be used by artists. High end crafts and mixed media artists are using more and more synthetic, recyclable, and/or environmentally friendly products in their original art so it is the framer's job to be familiar with them.

I highly recommend purchasing a few sheets synthetic paper, synthetic fiber paper, and stone paper to try mounting methods so you feel comfortable discussing mounting options with your customers. That said, once there is art medium applied they are originals that may respond differently, and remember we should only mount originals using fully reversible preservation techniques.

END

Copyright © 2021 Chris A Paschke

Resources—Items

https://www.spunart.co.uk/lutradur-heat-distressing-1—Lutradur, Evolon

https://yupousa.com—Yupo

https://www.neschen.de/en/product/gudy-802—gudy 802 PSA film

https://www.thethreadstudio.com/catalogue/fab/fab9.htm—Evolon, Lutradur, Zeelon (UK)

https://www.dickblick.com—Evolon

https://www.talasonline.com/Evolon-CR-Non-Woven-Textile—Evolon, Evolon CR, Evolon AR

https://www.talasonline.com/Dupont-Tyvek—Tyvek Smooth Texture & Soft Structure

http://terraskin.org—TerraSkin

Carolyn Burns Study

Burns, Carolyn. Characterization of Four Modern Papers

"Polyethylene and polypropylene are thermoplastic polymers that offer some chemical resistance; however, they have poor long term stability, especially upon exposure to UV radiation, oxygen, heat, and high relative humidity. The fading and marks from handling suggest these papers should be stored and displayed with UV filtration and controlled RH, and handled with gloves," states Art Conservationist Carolyn Burns in her research paper Characterization of Four Modern Papers, at Buffalo State University.

Suggested areas for further investigation include: light, heat, and moisture aging studies; interactions between surface coatings and media; and solubility and effects of cleaning of surface coatings.

For more articles on mounting basics look under the mounting section in Articles by Subject.

Additional information on all types of mounting is found in:

The Mounting and Laminating Handbook, Second Edition, 2002,

The Mounting And Laminating Handbook, Third Edition, 2008 and

Creative Mounting, Wrapping, And Laminating, 2000 will teach you everything you need to know about getting the most from your dry mount equipment and materials as an innovative frame designer.

All books are available from Designs Ink Publishing through this website.

Chris A Paschke, CPF GCF

Designs Ink

Designs Ink Publishing

785 Tucker Road, Suite G-183

Tehachapi, CA 93561

P 661-821-2188

chris@designsinkart.com