Photo 1

Photo 1

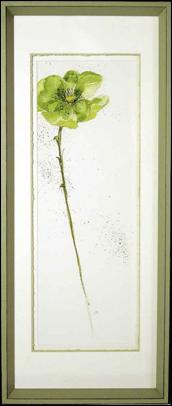

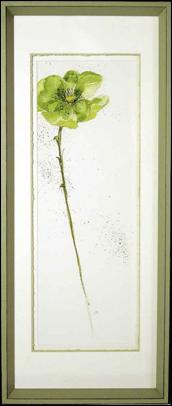

"Mint Poppies" by Chris Paschke One of a pair of 7x22" originals framed for a bathroom as 11x28" completed frames.

A sealed frame is one that has been treated and/or prepared to tolerate extremes of moisture and humidity in order to protect the housed art from damage. This could be the result of catastrophic immediate one time exposure—hurricane or flood—or slower long term degradation such as being displayed on a yacht or moist exterior brick basement wall. Though situations such as these may be rare in dry arid regions of New Mexico and the high deserts of California, damage is far more possible in lush, humid areas of the country.

Earlier this year I sold eight original paintings to a collector in Chicago, IL. A pair of these original watercolor and ink florals were to be framed and prominently displayed in the guest bathroom—where the shower would also be routinely used—so it was decided that sealing the frames would better protect the original art (photo 1). A sealed frame looks no different from any custom framed piece, but will require a little more depth inside the rabbet comprised to accommodate the sandwich of two sheets of glass, mats, backing, and sealing products (photo 2) and the frame lip width should be a minimum of ⅜".

Photo 1

Photo 1

"Mint Poppies" by Chris Paschke One of a pair of 7x22" originals framed for a bathroom as 11x28" completed frames.

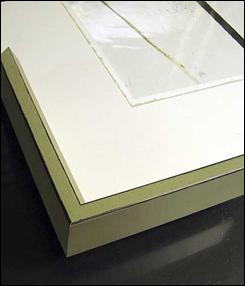

Photo 2

Photo 2

Sealed sandwich includes UV glass, double rag mats with spacer and deckled paper accent and backing glass edge sealed with Marvelseal in an 11x28" Nurre Caxton 3998 Sage moulding.

Sealing Materials

A sealed frame system helps protect art from the potential damaging effects of environmental surroundings including changing humidity, atmospheric pollutants, dust, mold, and bugs. Glass serves as a basic barrier in the front and back of the frame package complete with buffered inner boards but the edges still remain open and accessible to moisture and pollution, so the edges must be heat sealed to keep those elements out.

Dust covers are implemented in framing as a protection against minor invasion of such items, but simply by replacing a paper cover with a polypropylene backing or the multilayer aluminized nylon and polyethylene barrier film does nothing to protect open edges. An alternative to a porous dust cover is Coroplast, a chemically inert, durable polypropylene copolymer, extruded fluted plastic sheet, free from additives such as coloring agents which is antistatic and has ultraviolet inhibitors. It does not out-gas, is resistant to water, oils, and solvents at room temperatures, and is excellent for making boxes, backing stretched canvases, and as a barrier board. It is available in various thicknesses, up to 48x96" from numerous suppliers…but it does not create a sealed package.

Talas, Gaylord and University Products sell MarvelSeal 360, a flexible, heat-sealable, aluminized nylon and polyethylene barrier film that resists the passage of moisture, vapors, atmospheric gases and pollutants. This easy to fabricate material is used for passive humidity control during framing, lining of transport crates, and heat-seals at 350ºF for long term storage bags, such as freeze-dried foods. In a sealed frame, this impervious film wraps around the back and up the sides of the inner sandwich to the front and is heat sealed to the front glass.

Even when not creating a full blown sealed package, Volara helps with moisture protection. Volara is a cross linked polyethylene closed-cell foam with a smooth surface, chemical resistance, and thermal insulation. Volara Foam Rabbet Tape is a ¼" wide x ¹⁄₃₂" thick strip of Volara material coated with aggressive acrylic adhesive which adheres tightly to the frame rabbet to cover the raw wood to protect an art package (photo 3). It features low water absorption and vapor transmission, excellent chemical resistance and thermal insulation.

ArtSorb, is a moisture-sensitive silica material designed to stabilize moisture in order to offset changes in relative humidity. Sheets have the ability to absorb up to 5 times the normal capacity of silica gel and are ideal for framed works and displays where depth of space is limited. A sheet may be added to a package to assist in the absorption of excess moisture when it may be difficult to condition package materials to 50% RH.

Photo 3

Photo 3

Volara Foam Rabbet Tape is ¼" wide x ¹⁄₃₂" thick polyethylene closed-cell foam with aggressive acrylic adhesive.

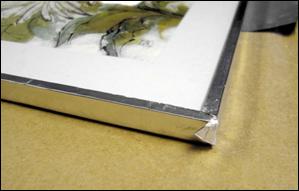

P-S Tape vs. Hot Melt

MarvelSeal is eventually heat-set to seal the package, but first is temporarily held to the package edges using either 3M 969, a chemically stable, high tack, 5 mil thick ATG tape or 3M 415 a permanent, double-sided, pressure-sensitive acrylic adhesive that won't crack or yellow—which is frequently selected for polyester encapsulation (photo 4). The weakest links in any sealed package are the pressure-sensitive tapes and potential air leaks at the corners or seams due to inadequate bonding technique. Air gaps can be created where tapes are overlapped which may not be flattened without burnishing and heat application.

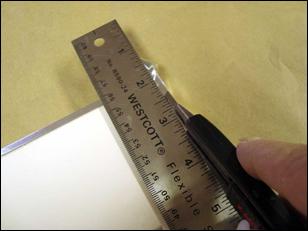

Photo 4

Photo 4

Materials include roll of MarvelSeal 360, 3M 415, ruler, knife and tacking iron.

Another adhesive option is either 3M Scotch-Weld 3797 TC—formerly 3M Jet-Melt #3797—a 100% solid thermoplastic, high temperature resistant adhesive or 3M Scotch-Weld 3748 TC, both are 2" x ⅝" sticks of off-white, electrical-grade hot melt adhesive. A 3M Scotch-WeldHot Melt Applicator TC (385ºF / 196ºC) is required to apply this adhesive. These high temperature hot glue sticks bond well to polyethylene (MarvelSeal) and polypropylene and are unaffected by changes in altitude, temperature and relative humidity.

If selecting hot glue sticks over tape the application is basically the same as described below, but after initially creating the heat bond—including the corners—then the final setting is done with a second go-round of heat application. If hot glue oozes from under the edge of the aluminum barrier when heat-setting it is a sign of full melting and is not a problem. Once cooled, the barrier film should be trimmed to fit beneath the frame lip.

The Chicago Project

Once the mat package has been completed size a sheet of MarvelSeal allowing 1" on all sides for package completion (photo 5). There is one shiny, one dull matte side. The matte finish is the side bonded to the adhesive tape and glass, so the shiny, nylon will face the outside of the package.

Photo 5

Photo 5

Size MarvelSeal sheet allowing 1" beyond on all sides. Matte side is against the back of the mat.

Glass is required for both front and back of the package because acrylic sheeting still allows elements to pass through. Dull the edges of the glass so they do not cut through the barrier film, then wipe the glass edges with alcohol to remove grease and fingerprints prior to the application of the selected tape or adhesive.

Fit the glass to the top of the mat package and run 3M 415 ¼" ATG tape to the outer ⅛" of the top of the cleaned glass (photo 6). The tape on the surface must fully fit beneath the lip of the rabbet. Activate the tape with hand burnishing and bone folder for adhesion to the glass (photo 7) then remove release liner to expose tape one side at a time during fusion.

Photo 6

Photo 6

With sandwich assembled—glass, mats with art, backing, glass—apply 3M415 tape along edge.

Photo 7

Photo 7

Burnish tape to activate adhesive prior to removing liner.

Wrap the silver barrier snugly up one side, press and burnish onto the ATG to hold for heat bonding, then apply medium-high heat with a dial control—not preset—tacking iron to fuse barrier and tape to the glass, making certain to fully iron each side from corner to corner to create a complete seal (photo 8). When the aluminum film wrinkles it has efficiently bonded to the glass, see the outer edge of photo 9. Move to the opposite side—as when stretching a canvas—and snugly lift then press to ATG on the opposite edge, then iron to bond. The MarvelSeal must be fully activated and well fused along all sides and into the corners to prevent air leaks so iron the corners from both directions and across the top edges to ensure bonding (photo 10). Once fused, trim the excess barrier film just short of the rabbet lip width so it is not visible (photo 11).

Photo 8

Photo 8

MarvelSeal around edges and stick to tape. Press the flat side of the iron working the full side from corner to corner.

Photo 9

Photo 9

Wrap matte side of film to ATG tape, shiny side out. Note the outer edge shows the film has been melted to the tape.

Photo 10

Photo 10

Securely seal corners by ironing in both directions.

This completed package is fully enclosed across the back and up the sides to the front of the matted unit (photo 12). Though the process takes a little practice, once mastered it should be in the repertoire of all custom framers. Just remember that the conditioning aspect is the biggest concern.

Photo 11

Photo 11

Trim away excess silver film leaving ⅛" fused film to glass.

Photo 12

Photo 12

MarvelSeal wrap completely covers back and edges of frame package.

Conditioning Concerns

A serious concern over sealing is the potential for trapping elements into the package, in some cases the very elements that the sealing is meant to keep out. Airborne bacteria, anaerobic bacteria (not requiring air), pollution, mold, and moisture can all be trapped within the package allowing for future damage. If a package is sealed in a humid environment mold will develop inside the frame as there is no air circulation so for proper preservation everything inside the package must be conditioned to 50% RH (relative humidity) at 70ºF.

Living in the high mountain desert the relative humidity and temperature fall into the average requirements so no heroic measures were made to condition the materials used in this project. It should be noted that the only air inside the package is that within the window and between the inner boards, which amounts to very little. Since it is protected from additional humidity by being sealed even as the temperature raises and drops, any moisture remaining in the enclosed air will be easily absorbed into the boards causing no damage.

Full Service

Three padded and insulated shipping boxes were created for the relocation of eight framed originals to Chicago and currently the "Mint Poppy" pair is happily living in the guest bathroom. Today's full service custom frame shop should be capable of everything from locating a high end, custom carved, special-ordered, gold leaf frame to clever creative in-house mat designs and everything in between—including the production of a basic sealed package.

END

Copyright © 2014 Chris A Paschke

Resources—Items

http://gaylord.com—MarvelSeal, Volara, 3M 415, Coroplast

http://talasonline.com—MarvelSeal, Rabbet Tape, ArtSorb

http://universityproducts.com—MarvelSeal, Adhesive backed Volara, Coroplast

http:/hollingermetaledge.com—Silica Gel, Volara, 415, MarvelSeal 360

http://lightimpressionsdirect.com—3M 415, Coroplast

http://rshughes.com—3M Jet-Melt 3748 TC

http://solutions.3m.com—Scotch-Weld 3797-TC, 3748-TC

http://ellsworth.com—3M Polygun TC, 3748 TC, 3797 TC

For more articles on mounting basics look under the mounting section in Articles by Subject.

Additional information on all types of mounting is found in:

The Mounting and Laminating Handbook, Second Edition, 2002,

The Mounting And Laminating Handbook, Third Edition, 2008 and

Creative Mounting, Wrapping, And Laminating, 2000 will teach you everything you need to know about getting the most from your dry mount equipment and materials as an innovative frame designer.

All books are available from Designs Ink Publishing through this website.

Chris A Paschke, CPF GCF

Designs Ink

Designs Ink Publishing

785 Tucker Road, Suite G-183

Tehachapi, CA 93561

P 661-821-2188

chris@designsinkart.com